![]() Brand Name: IMAKO

Brand Name: IMAKO

![]() Price: Negotiable

Price: Negotiable

![]() Model Number: TP-H150

Model Number: TP-H150

![]() Power: 30.5KW

Power: 30.5KW

![]() Application: handkerchief paper

Application: handkerchief paper

![]() Weight: 9500kg

Weight: 9500kg

![]() Output: 120Pack/min

Output: 120Pack/min

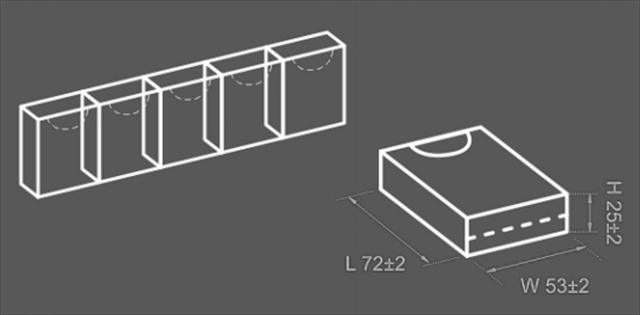

![]() Packaging dimension: Length (L): 72±2/105±2 Width (W): 53±2/53±2 Height (H): 25±2/25±2 MM

Packaging dimension: Length (L): 72±2/105±2 Width (W): 53±2/53±2 Height (H): 25±2/25±2 MM

![]() Place of Origin: CHINA.

Place of Origin: CHINA.

![]() Certification: CE, ISO

Certification: CE, ISO

![]() Minimum Order Quantity: 1 SET

Minimum Order Quantity: 1 SET

![]() Trading Method: FOB/CIF/EXW Xiamen Port

Trading Method: FOB/CIF/EXW Xiamen Port

![]() Delivery Time: 90 Days

Delivery Time: 90 Days

![]() Packaging logistics: In wooded cases with fumigation finish or wrapped with plastic film.

Packaging logistics: In wooded cases with fumigation finish or wrapped with plastic film.

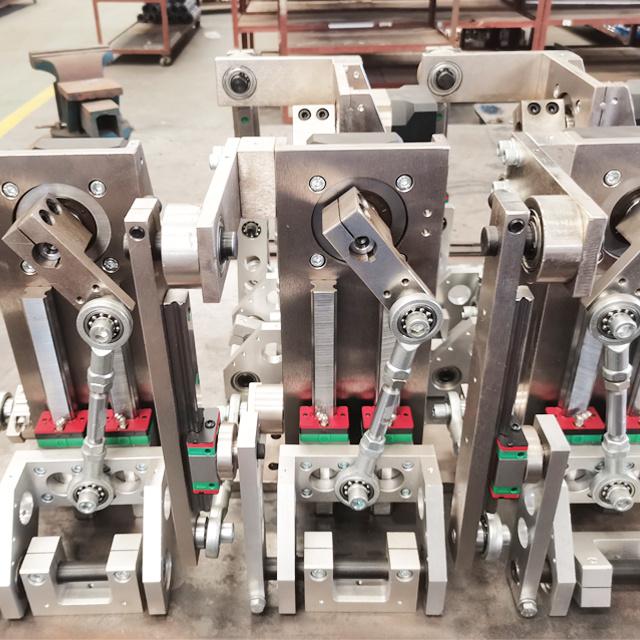

The machine combine the high qualification rate and effective productivity to one, save labor and raw material cost. Control system is completely self-contained, run stably. Use surface is positive, few and short Fold; Cutting side is smooth, no black and burr; Regular fold, derangerment is 2 mm, no inner fold. And backslash; Side embossing is symmetrical and clear, no delaminating.

|

TP-H150 handkerchief paper packaging machine main parameter configuration |

|||

|

Specification/Model/ ltem |

TP-H150 |

||

|

Unwinders |

Dual unwanders |

One use one spare |

|

|

Jumbo roll dia. |

≤1500 |

||

|

Tissue open size |

Width 205-210 |

||

|

Length 205-210 |

|||

|

Gram weight(g/Cm) |

2Ply 18-20 |

||

|

3Ply 13-16 |

|||

|

4Ply 12-14 |

|||

|

Power supply |

380V/50HZ |

||

|

Packaging film material |

CPP、PE |

||

|

Packaging film thickness(mm) |

0.04~0.05 |

Single pack and bundle pack need to use different film material |

|

|

Film roll diameter(mm) |

≤380 |

||

|

Design speed |

130packs/min according to 10 sheets |

||

|

Stable speed |

110packs/min according to 10 sheets |

||

|

Perforation |

U or V type |

||

|

Air compression(MPA) |

0.6 |

||

|

Air flow |

300 |

||

|

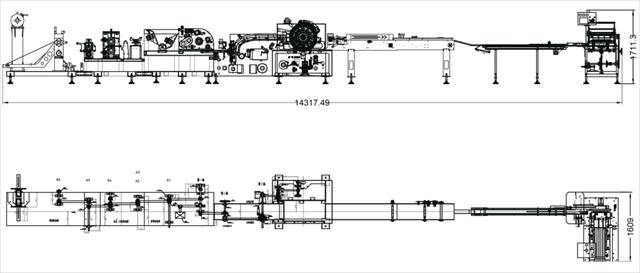

Machi'ne dimension(mm) |

16100x2000x2000 |

Includes bundle packing machine |

|

|

Machine weight(KG) |

9500 |

||

|

Optional device |

Hydraulic system, pneumatic system, point to flat embossing, point to concave embossing. point to point embossing. |

||

The machine combine the high qualification rate and effective productivity to one, save labor and raw material cost.

The machine combine the high qualification rate and effective productivity to one, save labor and raw material cost. Control system is completely self-contained, run stably....

Adopts servos control for tissue arrangement, counting, stacking, tissue fill to bag, bag catching, bag conveying, bag opening and seal parts, This machine is easy to operation and main...

TP-T300 multi servo large size facial tissue single wrapping machine is suitable for automatically packing facial tissue paper, V fold wipes, napkins or similar Non-woven fabric, dust-f...

Adopts servos control for tissue arrangement, counting, filling preparation, tissue fill to bag, bag catching, bag conveying, bag opening and seal parts, This machine is easy to operati...