Author:IMAKO Tissue MachineFROM:Toilet Paper Machine Manufacturer TIME:2023-10-13

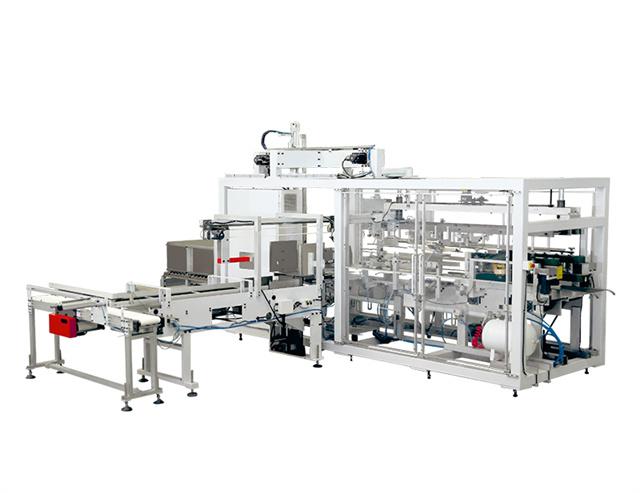

Utilizing the rolls carton packing machine effectively is crucial for businesses in the packaging industry. This advanced technology streamlines the packaging process, improves efficiency, and ensures the safety of the packaged items. However, to maximize the benefits of this machine, it is important to understand its features and proper operation. In this article, we will explore three key factors to consider when utilizing the rolls carton packing machine effectively.

Before using the rolls carton packing machine, it is essential to set it up correctly and calibrate it properly. This ensures that the machine functions optimally and delivers accurate results. Start by checking the machine's components, such as the conveyor belts, rollers, and sensors, to ensure they are clean, lubricated, and in good condition. Adjust the machine settings based on the carton size, weight, and packaging requirements. Calibration is crucial to ensure precise dimensional measurements and avoid errors during the packing process.

To utilize the rolls carton packing machine effectively, it is necessary to load the rolls and operate the machine efficiently. Firstly, select the appropriate rolls of cartons, considering factors such as strength, size, and flexibility. Load the rolls onto the machine, ensuring they are aligned correctly and securely fixed. It is crucial to follow the recommended loading capacity and not overload the machine, as this can cause malfunction and affect the quality of packaging. When operating the machine, pay attention to the speed and direction of the conveyor belts, as well as the stacking and sealing mechanisms. Regularly monitor the machine's performance and address any issues promptly.

Quality control and maintenance are essential elements for effectively utilizing the rolls carton packing machine. Implement regular quality checks to ensure that the machine consistently produces packaging of the desired standards. Inspect the sealed cartons for any defects, such as incorrect folding, inadequate sealing, or damaged corners. Additionally, conduct routine maintenance tasks such as cleaning, lubricating, and replacing worn-out parts. Regular maintenance not only improves the machine's longevity but also optimizes its performance and reduces the likelihood of breakdowns and costly repairs.

In conclusion, to utilize the rolls carton packing machine effectively, businesses should focus on machine set-up and calibration, efficient loading and operation, and quality control and maintenance. By paying attention to these factors, companies can optimize the machine's performance, streamline their packaging processes, and enhance overall efficiency. Utilizing this advanced technology effectively is an investment in productivity, accuracy, and customer satisfaction.