![]() Price: Negotiable

Price: Negotiable

![]() Model Number: 320REM

Model Number: 320REM

![]() Power: 12KW

Power: 12KW

![]() Application: toilet paper packing machine

Application: toilet paper packing machine

![]() Weight: 3000kgs

Weight: 3000kgs

![]() Output: 50p/min

Output: 50p/min

![]() Packaging dimension: TBN

Packaging dimension: TBN

![]() Place of Origin: CHINA.

Place of Origin: CHINA.

![]() Brand Name: IMAKO

Brand Name: IMAKO

![]() Certification: CE, ISO

Certification: CE, ISO

![]() Minimum Order Quantity: 1 SET

Minimum Order Quantity: 1 SET

![]() Trading Method: FOB/CIF/EXW Xiamen Port

Trading Method: FOB/CIF/EXW Xiamen Port

![]() Delivery Time: 90 Days

Delivery Time: 90 Days

![]() Packaging logistics: In wooded cases with fumigation finish or wrapped with plastic film.

Packaging logistics: In wooded cases with fumigation finish or wrapped with plastic film.

★Maximum stable packing speed of roll paper with core: 200 rolls/min

★Maximum stable packing speed of coreless roll paper: 150 rolls/min

★Can realize length changing from 80-220mm by setting on touch screen directly.

★Standard functions equipped: Inching function, line function,diameter error detection and alarm function, length error detection and alarm function, film stop feeding when no material function

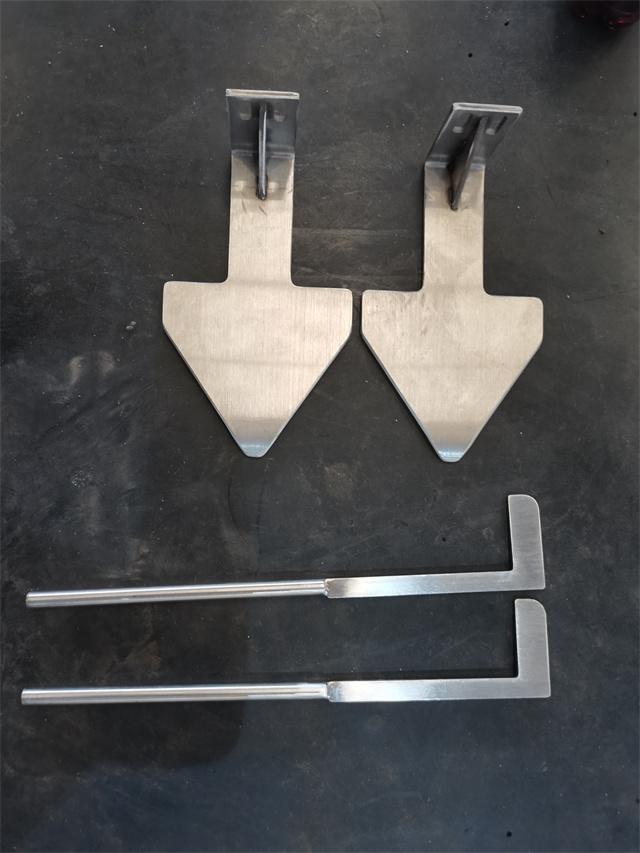

* Automatic open / close of fin seal roller

* Film feeding stops when there is no tissue roll

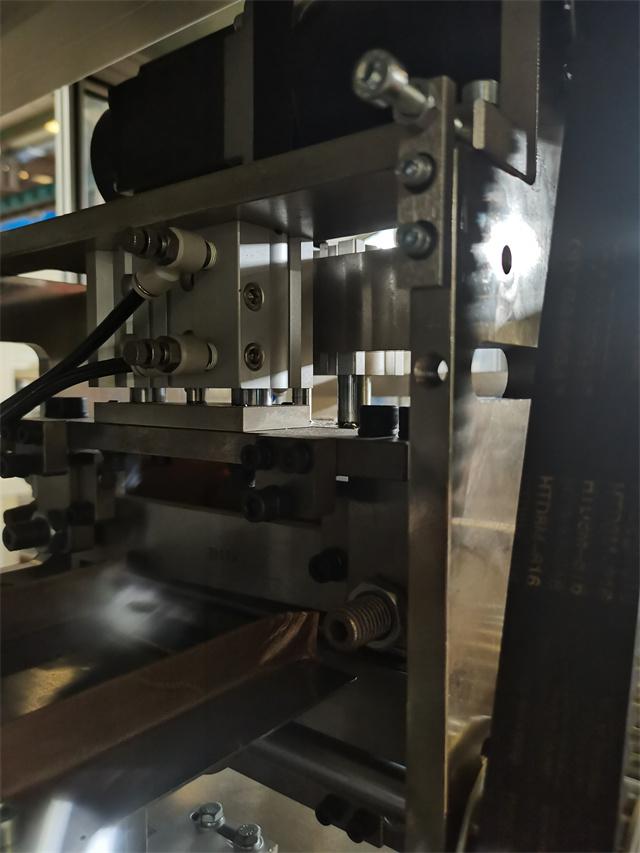

★TP-R220 automatic single roll paper wrapping machine is suitable for auto packing core/coreless toilet paper rolls and kitchen tissue rolls.

★ Adopts servos control for tissue arrangement, counting, stacking, tissue fill to bag, bag catching, bag conveying, bag opening and seal parts, This machine is easy to operation and ...

Toilet paper, as an essential consumer product, has become a necessity in daily life. The production of toilet paper is undertaken by a type of machinery known as atoilet paper maker. I...

★ Adopts servos control for tissue arrangement, counting, stacking, tissue fill to bag, bag catching, bag conveying, bag opening and seal parts, This machine is easy to operation and ...

Finished Product ★Maximum stable packing speed of roll paper with core: 200 rolls/min ★Maximum stable packing speed of coreless roll paper: 150 rolls/min ★Can realize length ch...