![]() Price: Negotiable

Price: Negotiable

![]() Model Number: TP-B30R

Model Number: TP-B30R

![]() Power: 20.2KW

Power: 20.2KW

![]() Application: single packed/unpack core/coreless roll paper

Application: single packed/unpack core/coreless roll paper

![]() Weight: 3400KG

Weight: 3400KG

![]() Output: 22Pack/min

Output: 22Pack/min

![]() Packaging dimension: L(170-660) /W(180-260) /H(85-170)MM

Packaging dimension: L(170-660) /W(180-260) /H(85-170)MM

![]() Place of Origin: CHINA.

Place of Origin: CHINA.

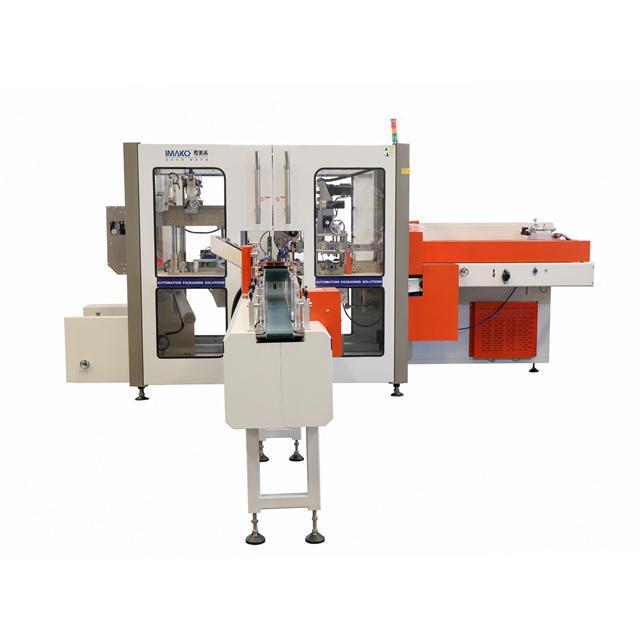

![]() Brand Name: IMAKO

Brand Name: IMAKO

![]() Certification: CE, ISO

Certification: CE, ISO

![]() Minimum Order Quantity: 1 SET

Minimum Order Quantity: 1 SET

![]() Trading Method: FOB/CIF/EXW Xiamen Port

Trading Method: FOB/CIF/EXW Xiamen Port

![]() Delivery Time: 90 Days

Delivery Time: 90 Days

![]() Packaging logistics: In wooded cases with fumigation finish or wrapped with plastic film.

Packaging logistics: In wooded cases with fumigation finish or wrapped with plastic film.

|

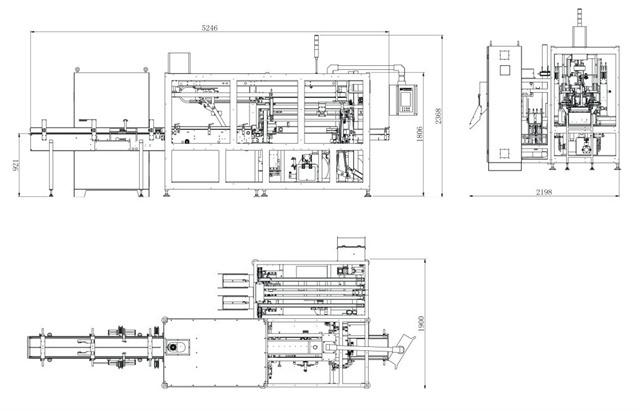

TP-B30R main parameter configuration |

||

|

Specification/Model/ ltem |

TP-B30RV、TP-B30RM |

|

|

Scope of application |

Single core/coreless roll paper |

|

|

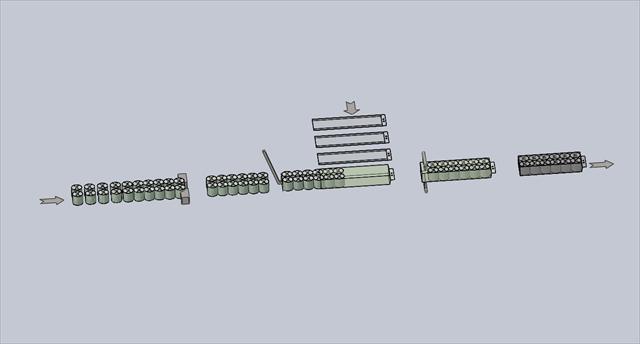

Feeding type |

ASF automatic double lanes intelligent feeding system |

Exclude standing device |

|

Design speed |

25 packs/min |

relate to product size |

|

Stable speed |

15-22 packs/min |

relate to product size |

|

Packaging film install structure |

Dual bag racks |

|

|

Gusset type |

Vacuum mould |

|

|

Scrap cut off mode |

Insert & cut teeth share |

|

|

Bag storage QTY |

600 pre-bag |

Can customize if size exceed |

|

Machine weight(KG) |

3400 |

|

|

Bag material |

PE film |

Thickness 0.05mm |

|

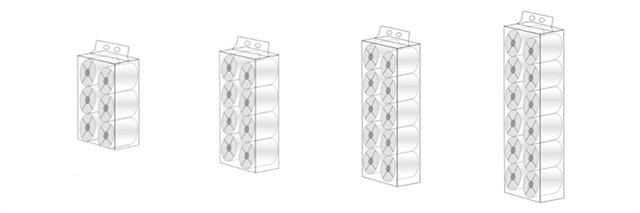

Packing style(mm) |

①L90-170 D.90-105 |

Suitable for corel coreless roll paper |

|

2x3、 2x4、2x5、2x6 |

||

|

②L85-170 D.90-130 |

||

|

2x3、2x4、2x5 |

||

|

Air compression(MPA) |

Pressure 0.6 Flow 300Lmin |

Buyer provide |

|

Bag type |

Pre-bag |

Air hole≥2.5mm |

Small scale tissue paper making machines are a great investment for those who want to start their own small business. These machines are affordable, easy to use and maintain, and can produce high-quality tissue papers that can be sold in the market. In this article, we will discuss the benefits of investing in a small scale tissue paper making machine.

One of the biggest advantages of a small scale tissue paper making machine is its low investment cost. These machines are designed for small businesses and individuals who have limited budgets. You can purchase a basic machine for as little as $1000, and a more advanced model for around $3000. This investment is relatively low compared to other types of machinery in the paper industry. Once you have purchased the machine, you will only need to buy raw materials and maintain the machine, which will also cost you less than larger scale machines.

Small scale tissue paper making machines are designed to be user-friendly. They are easy to operate and require minimal training. Most of these machines come with an instruction manual that will guide you through the process of using the machine. Additionally, they are easy to maintain. You will only need to clean and oil the machine regularly, and replace the parts when necessary. Unlike large machines, small scale tissue paper making machines do not require a team of technicians to operate and maintain them. You can do it all by yourself.

Another benefit of investing in a small scale tissue paper making machine is that you can produce high-quality tissue papers that meet industry standards. The machine is designed to produce tissue papers of different sizes and thicknesses. You can create custom designs and patterns on the tissue papers to make them more attractive to consumers. Furthermore, the machine is equipped with features that help you produce tissue papers that are soft, absorbent, and durable. The end-product will be of superior quality, which can help you build a good reputation in the market.

In conclusion, investing in a small scale tissue paper making machine is an excellent opportunity for individuals who want to start their own small business or expand their existing business in the paper industry. The low investment cost, easy operation and maintenance, and high-quality tissue paper production make it an attractive investment. With the right skills and strategies, you can make a profit by producing and selling tissue papers using this machine.

TP-B30R series automatic roll paper bundle packing machine is suitable for automatic bundle packing single packed/unpack core/coreless roll paper.

Toilet paper production line refers to the manufacturing process used to produce toilet paper, which is a soft and absorbent paper product primarily used for cleaning after defecation o...

Main performance and structure features 1. Double transducer control, easy maintained, decreasing abrasion with long life. 2. human-machine operation, convenient and quick parame...

When it comes to toilet paper production, the fully automatic toilet paper making machine is a game changer. This advanced technology makes it possible for companies to produce high-qua...

The creation of toilet paper is one of the most important inventions in the history of personal hygiene. Toilet paper making machines have made it easier for manufacturers to produce to...