![]() Price: Negotiable

Price: Negotiable

![]() Model Number: TP-R220

Model Number: TP-R220

![]() Power: 15.2KW,380V/60Hz

Power: 15.2KW,380V/60Hz

![]() Application: Single core and coreless toilet paper rolls

Application: Single core and coreless toilet paper rolls

![]() Weight: 1800KG

Weight: 1800KG

![]() Output: 200 Packs/Min

Output: 200 Packs/Min

![]() Packaging dimension: Length (L): 80-220 Diameter(D) 80-130 mm

Packaging dimension: Length (L): 80-220 Diameter(D) 80-130 mm

![]() Place of Origin: CHINA.

Place of Origin: CHINA.

![]() Brand Name: IMAKO

Brand Name: IMAKO

![]() Certification: CE, ISO

Certification: CE, ISO

![]() Minimum Order Quantity: 1 SET

Minimum Order Quantity: 1 SET

![]() Trading Method: FOB/CIF/EXW Xiamen Port

Trading Method: FOB/CIF/EXW Xiamen Port

![]() Delivery Time: 90 Days

Delivery Time: 90 Days

![]() Packaging logistics: In wooded cases with fumigation finish or wrapped with plastic film.

Packaging logistics: In wooded cases with fumigation finish or wrapped with plastic film.

When it comes to toilet paper production, the fully automatic toilet paper making machine is a game changer. This advanced technology makes it possible for companies to produce high-quality toilet paper in large quantities, without compromising on efficiency or quality.

The fully automatic toilet paper making machine is able to carry out all the necessary processes involved in toilet paper production, from cutting and pasting to winding and sealing, without any human intervention. This greatly reduces the risk of errors and delays, resulting in significantly higher productivity levels. This means that companies can produce more toilet paper in less time, at a lower cost, enabling them to keep up with demand and increase their profits.

The fully automatic toilet paper making machine also ensures a consistently high level of quality throughout the entire production process. This is because the machine follows a pre-determined set of instructions and has built-in sensors that detect any irregularities in the production process. This means that there are fewer defects in the final product, resulting in higher customer satisfaction rates and a stronger reputation for the company.

The fully automatic toilet paper making machine also leads to significant cost savings for companies. This is because it eliminates the need for manual labor and reduces the risk of material waste, resulting in lower production costs. Additionally, the machine requires minimal maintenance and has a long lifespan, meaning that companies can save on repair and replacement costs in the long run.

In conclusion, the fully automatic toilet paper making machine is a crucial tool for companies involved in toilet paper production. With its ability to increase productivity, improve quality, and save costs, it is no wonder that this technology is becoming increasingly popular among industry players.

Suitable for packing roll paper, such as roll tissue, code applying paper and cash register paper etc.

|

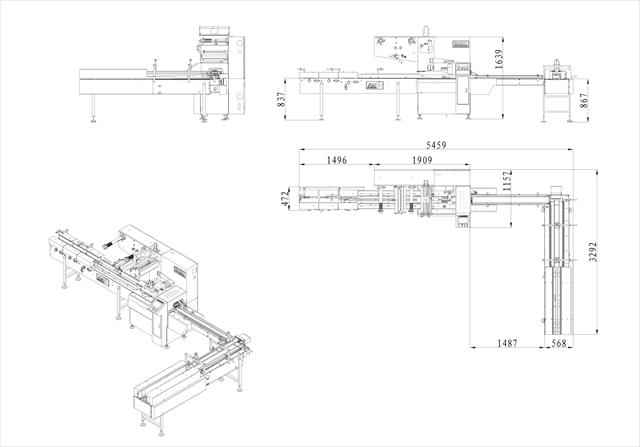

Max. Work Speed: |

200Pack/min |

|

Total Power: |

12KW |

|

Pack Range(mm): |

Length (L): 80-220 Diameter (D): 80-130 |

The creation of toilet paper is one of the most important inventions in the history of personal hygiene. Toilet paper making machines have made it easier for manufacturers to produce toilet paper in bulk, helping to supply a growing population's needs. Here, we'll dive into the details of these machines to better understand how they work and what makes them so essential.

Toilet paper making machines are complex pieces of machinery that play a crucial role in creating this iconic product. These machines are designed to turn raw materials such as wood pulp or recycled paper into the soft and fluffy toilet tissue that we all know and use in our daily lives. The process begins with raw materials being fed into a pulping machine that turns them into a fine pulp. This mixture is then sent to the main production machine where it is converted into sheets of toilet paper.

Quality control is a vital part of any toilet paper manufacturing operation. It ensures that the final product is safe, hygienic and of a consistent quality. Modern toilet paper making machines are equipped with built-in quality control systems that help manufacturers to minimize waste and detect problems early in the production process. These systems use sensors and other technologies to monitor factors such as paper thickness and moisture levels, allowing operators to adjust the machine's settings as needed.

Modern toilet paper making machines offer significant benefits over their older counterparts. They are faster, more efficient and more reliable than ever before, allowing manufacturers to increase production while reducing costs. Additionally, many of these machines are designed to be easy to use and maintain, with most issues able to be fixed quickly and with minimal downtime. With the right tools and technology, manufacturers can meet the growing demand for toilet paper and ensure a steady supply for consumers around the world.

In conclusion, toilet paper making machines have become an integral part of the modern world. These complicated but essential pieces of technology ensure that we have a steady supply of high-quality toilet paper to meet our daily needs. As technology continues to improve, it's likely that toilet paper making machines will become even more efficient and reliable, helping us to maintain the highest standards of personal hygiene for years to come.

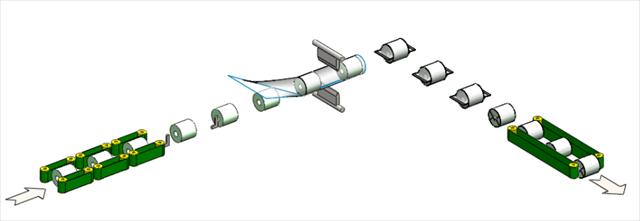

General function

Link conveyor system, auto monitor in feed rolls flow, machine auto-stop for limited rolls, rolls auto arrange and feed function, auto stop for abnormal operation and no facial tissue condition, auto alarm and stop for no film, film cutting position electronic auto adjust function, auto-memory and keep parameters function, main machine jog and separated action function, side-sealing part separated action function, whole machine linkage and emergency stop function, whole machine cycle stop and auto display defaults function.

Toilet paper is an essential item in our daily lives, and it's hard to imagine a world without it. Have you ever wondered how toilet paper is made and where it comes from? Well, in this...

★Adopts servos control for tissue arrangement, counting, filling preparation, tissue fill to bag, bag catching, bag conveying. This machine is easy to operation and maintenance. ★Ado...

Toilet paper production line refers to the manufacturing process used to produce toilet paper, which is a soft and absorbent paper product primarily used for cleaning after defecation o...

★Adopts servos control for tissue arrangement, counting, filling preparation, tissue fill to bag, bag catching, bag conveying. This machine is easy to operation and maintenance. ...