![]() Price: Negotiable

Price: Negotiable

![]() Model Number: TP-B30R

Model Number: TP-B30R

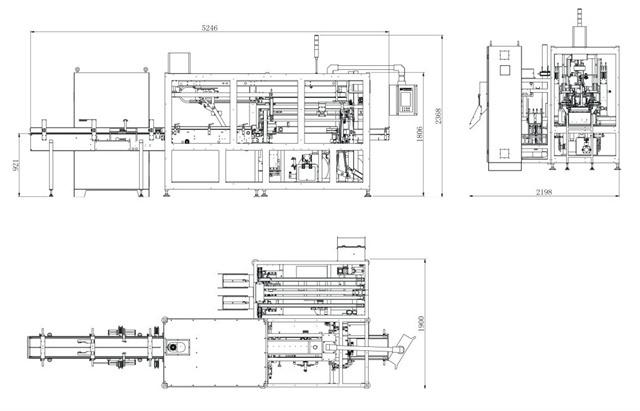

![]() Power: 20.2KW

Power: 20.2KW

![]() Application: single packed/unpack core/coreless roll paper

Application: single packed/unpack core/coreless roll paper

![]() Weight: 3400KG

Weight: 3400KG

![]() Output: 22Pack/min

Output: 22Pack/min

![]() Packaging dimension: L(170-660) /W(180-260) /H(85-170)MM

Packaging dimension: L(170-660) /W(180-260) /H(85-170)MM

![]() Place of Origin: CHINA.

Place of Origin: CHINA.

![]() Brand Name: IMAKO

Brand Name: IMAKO

![]() Certification: CE, ISO

Certification: CE, ISO

![]() Minimum Order Quantity: 1 SET

Minimum Order Quantity: 1 SET

![]() Trading Method: FOB/CIF/EXW Xiamen Port

Trading Method: FOB/CIF/EXW Xiamen Port

![]() Delivery Time: 90 Days

Delivery Time: 90 Days

![]() Packaging logistics: In wooded cases with fumigation finish or wrapped with plastic film.

Packaging logistics: In wooded cases with fumigation finish or wrapped with plastic film.

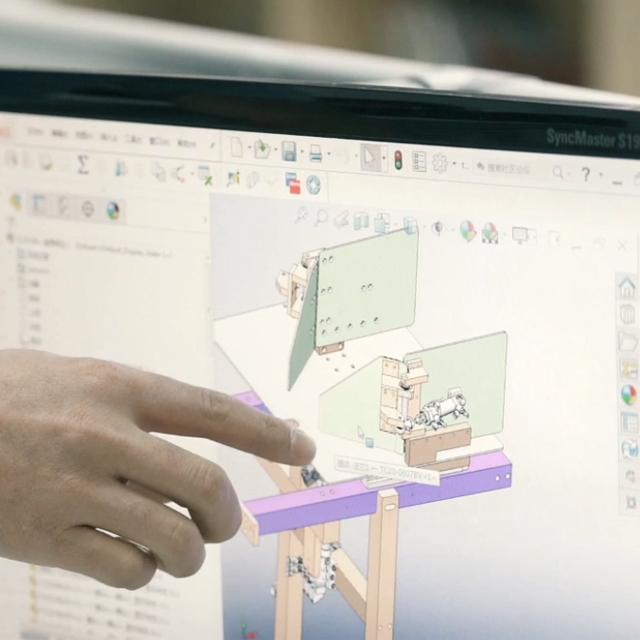

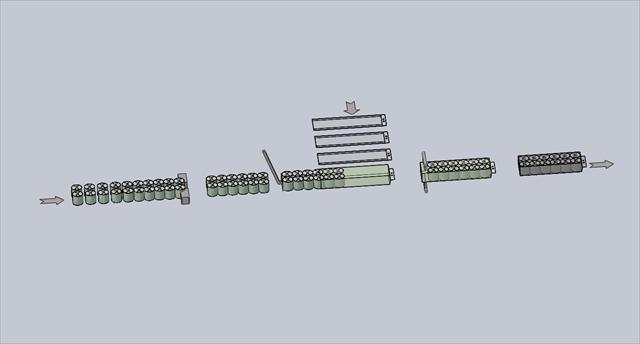

★Adopts servos control for tissue arrangement, counting, filling preparation, tissue fill to bag, bag catching, bag conveying. This machine is easy to operation and maintenance.

★Adopts central vacuum management mode, can efficiency lower power consumption.

★Adopts intelligent sealing system, alternating current control, up & down independent temperature control, can meet different kinds of packaging materials, ensure nice sealing and stably running.

★Equipped with functions of waste bag free stop automatic rejection, air source management, fault alarm and display, servo overload protection.

|

TP-B30R main parameter configuration |

||

|

Specification/Model/ ltem |

TP-B30RV、TP-B30RM |

|

|

Scope of application |

Single core/coreless roll paper |

|

|

Feeding type |

ASF automatic double lanes intelligent feeding system |

Exclude standing device |

|

Design speed |

25 packs/min |

relate to product size |

|

Stable speed |

15-22 packs/min |

relate to product size |

|

Packaging film install structure |

Dual bag racks |

|

|

Gusset type |

Vacuum mould |

|

|

Scrap cut off mode |

Insert & cut teeth share |

|

|

Bag storage QTY |

600 pre-bag |

Can customize if size exceed |

|

Machine weight(KG) |

3400 |

|

|

Bag material |

PE film |

Thickness 0.05mm |

|

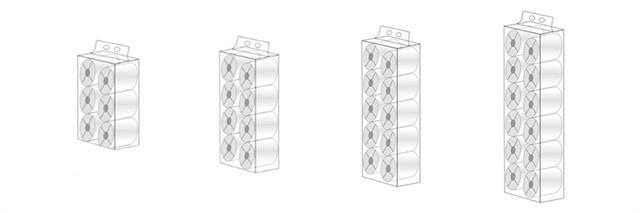

Packing style(mm) |

①L90-170 D.90-105 |

Suitable for corel coreless roll paper |

|

2x3、 2x4、2x5、2x6 |

||

|

②L85-170 D.90-130 |

||

|

2x3、2x4、2x5 |

||

|

Air compression(MPA) |

Pressure 0.6 Flow 300Lmin |

Buyer provide |

|

Bag type |

Pre-bag |

Air hole≥2.5mm |

TP-B30R series automatic roll paper bundle packing machine is suitable for automatic bundle packing single packed/unpack core/coreless roll paper.

Equipped with functions of waste bag free stop automatic rejection, air source management, fault alarm and display, servo overload protection.

Toilet paper is an essential item in our daily lives, and it's hard to imagine a world without it. Have you ever wondered how toilet paper is made and where it comes from? Well, in this...

Small scale tissue paper making machines are a great investment for those who want to start their own small business. These machines are affordable, easy to use and maintain, and can pr...

Toilet paper production line refers to the manufacturing process used to produce toilet paper, which is a soft and absorbent paper product primarily used for cleaning after defecation o...

★Adopts servos control for tissue arrangement, counting, filling preparation, tissue fill to bag, bag catching, bag conveying. This machine is easy to operation and maintenance. ★Ado...