![]() Price: Negotiable

Price: Negotiable

![]() Model Number: DP-T55

Model Number: DP-T55

![]() Power: 12KW

Power: 12KW

![]() Application: Cotton Tissue

Application: Cotton Tissue

![]() Weight: 2500KG

Weight: 2500KG

![]() Output: 55Pack/min

Output: 55Pack/min

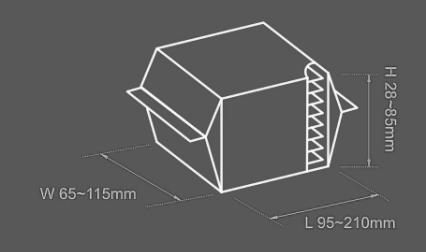

![]() Packaging dimension: Length (L): 95-210 ,Width (W): 65-115 ,Height (H): 28-85

Packaging dimension: Length (L): 95-210 ,Width (W): 65-115 ,Height (H): 28-85

![]() Place of Origin: CHINA.

Place of Origin: CHINA.

![]() Brand Name: IMAKO

Brand Name: IMAKO

![]() Certification: CE, ISO

Certification: CE, ISO

![]() Minimum Order Quantity: 1 SET

Minimum Order Quantity: 1 SET

![]() Trading Method: FOB/CIF/EXW Xiamen Port

Trading Method: FOB/CIF/EXW Xiamen Port

![]() Delivery Time: 90 Days

Delivery Time: 90 Days

![]() Packaging logistics: In wooded cases with fumigation finish or wrapped with plastic film.

Packaging logistics: In wooded cases with fumigation finish or wrapped with plastic film.

|

FA-P55 main parameter configuration |

|||

|

Specification/Model/ |

FA-P55 |

||

|

Scope of application |

Manually put material(can connect with palletizer) |

||

|

Design speed |

60 packs/min |

|

|

|

Stable speed |

≥55 packs/min |

|

|

|

Size mould |

3 sets |

|

|

|

Machine weight(KG) |

≤2500 |

||

|

Packaging material |

PE,CPP,OPP lamination film |

||

|

Film thickness(mm) |

0.04-0.08 |

||

|

Maximum film |

600 |

||

|

Fim core damater(mm) |

76 |

According to national standard |

|

Compressed air(MAP) |

Air compression ≥0.5 |

Buyer prepare |

|

Power supplier |

380V/ 50Hz |

According to national standard |

|

Suit voltage fluctuate |

+/-10% |

According to national standard |

|

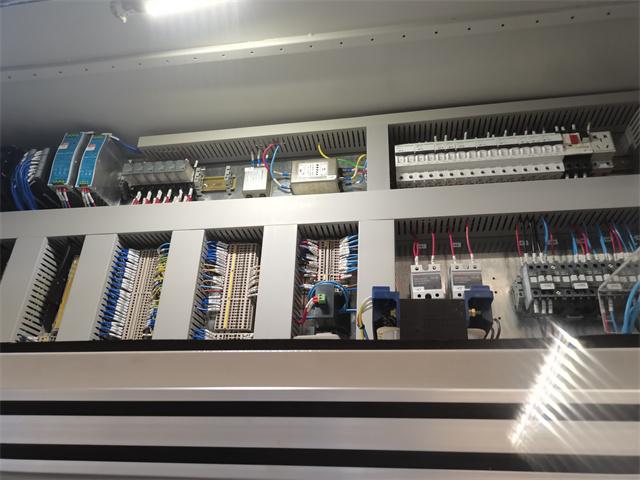

I/O input(VDC) |

24 |

Electrical control circle input |

|

I/O output (VDC) |

24 |

Electrical control circle output |

|

Machine movement control mode |

3 shafts servo shaft positoning control |

Electric cam movement curve |

|

Machine main transmission mode |

20 crmnti mechanical Cam + electric Cam transmission |

|

|

Machine color and craft |

Oyster grey,static spray plant craft |

|

|

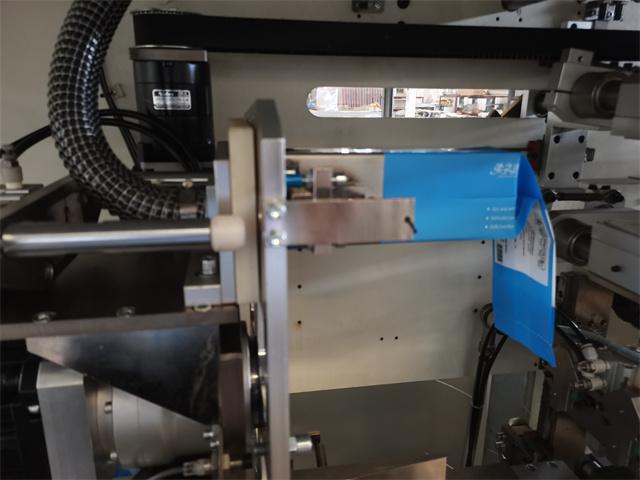

Packing type |

3D wrapping,both sides even sealing. |

|

| Max. Work Speed: | 55Pack/min |

| Total Power: | 12KW |

| Pack Range(mm): |

Length (L): 95-210 Width (W): 65-115 Height (H): 28-85 |

Adopts inverter to control film roll placing. Adopts servos for film pulling positioning, mold positioning, mold move and lift up, seal, fill into bag, bag open etc. Has advantages of ...

FA-P55 main parameter configuration Specification/Model/ ltem FA-P55 Scope of application Manually put material(can connect with palletizer) Des...