![]() Price: Negotiable

Price: Negotiable

![]() Model Number: DP-B3OD

Model Number: DP-B3OD

![]() Power:

Power:

![]() Application: conveying and sealing of bundle filled diaper

Application: conveying and sealing of bundle filled diaper

![]() Weight: 2000kc

Weight: 2000kc

![]() Output: 30Bags/Min

Output: 30Bags/Min

![]() Packaging dimension: L(200~600)/ W(160~460)/ H(100~200)

Packaging dimension: L(200~600)/ W(160~460)/ H(100~200)

![]() Place of Origin: CHINA.

Place of Origin: CHINA.

![]() Brand Name: IMAKO

Brand Name: IMAKO

![]() Certification: CE, ISO

Certification: CE, ISO

![]() Minimum Order Quantity: 1 SET

Minimum Order Quantity: 1 SET

![]() Trading Method: FOB/CIF/EXW Xiamen Port

Trading Method: FOB/CIF/EXW Xiamen Port

![]() Delivery Time: 90 Days

Delivery Time: 90 Days

![]() Packaging logistics: In wooded cases with fumigation finish or wrapped with plastic film.

Packaging logistics: In wooded cases with fumigation finish or wrapped with plastic film.

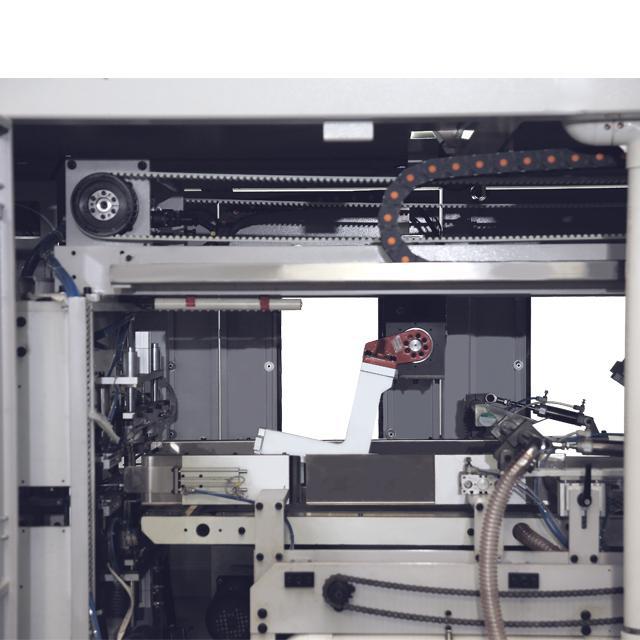

The machine adopts PLC cooperates with sensors to control diaper feeding and separating.

Adopt servos for sealing. It has advantages of complete working functions configuration,

high working efficiency

|

Packing Speed |

15-30(Bags/Min) |

|

Max.Production Speed |

30(Bags/Min) |

|

Machine Weight |

2000kg |

|

Machine Noise(DB) |

≤78db |

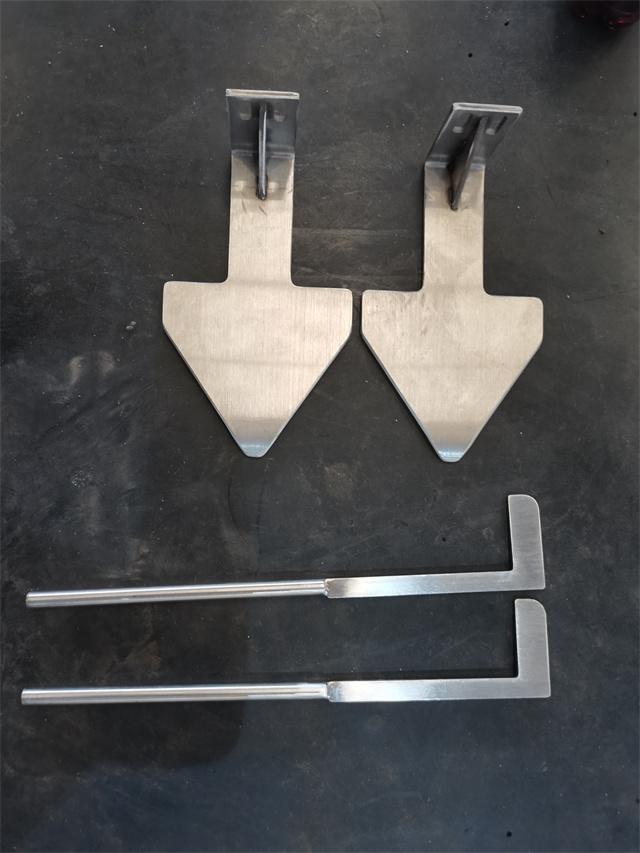

DP-B30D diaper packing machine is suitable for conveying and sealing of bundle filled diaper

The machine adopts PLC cooperates with sensors to control diaper feeding and separating.

Adopt servos for sealing. It has advantages of complete working functions configuration,

high working efficiency, easy to operate, wide sizes range, quick sizes changeover, easily

maintenance, low cost for using etc.

easy to operate, wide sizes range,quick sizes changeover, easily

maintenance, low cost for using etc.

The machine adopts PLC cooperates with sensors to control diaper feeding and separating.

Adopt servos for sealing. It has advantages of complete working functions configuration,

high working efficiency

Max,working speed 30bags per minute

DP-B2OD diaper packing machine is suitable for conveying and sealing of baby diaper,pull pants,adult pull pants,nursing pad etc....

high working efficiency, easy to operate, wide sizes range,quick sizes changeover, easily maintenance, low cost for using etc....

Adopts PLC cooperate with sensor to control diaper feeding and array. Use servo to control sealing and gusset unit. Has advantages of complete operation configuration, high efficiency, ...

Adopts PLC cooperate with sensor to control diaper feeding and array. Use servo to control bag filling and sealing. Has advantages of complete operation configuration, high efficiency, ...

We've been using the adult diaper packing machine for months now and couldn't be happier to operate and has reduced our packaging time by half!Harper 2024-06-05

we've seen a noticeable decrease in packaging errors. It's precise and ensures every diaper is properly sealed.Scarlett 2024-06-05

Our customers have been impressed with the quality of packaging since . It gives our products a professional finish.Madison 2024-06-05

It's efficient, reliable, and has significantly increased our output.Sophia 2024-06-05

allowing us to fulfill orders faster and more efficiently.Layla 2024-06-05