![]() Price: Negotiable

Price: Negotiable

![]() Model Number: DP-C20

Model Number: DP-C20

![]() Power: 380V/50HZ

Power: 380V/50HZ

![]() Application: baby diaper, pull pants,adult pull pants,nursing pad etc.

Application: baby diaper, pull pants,adult pull pants,nursing pad etc.

![]() Weight: 4000KG

Weight: 4000KG

![]() Output: 30 Bags/min

Output: 30 Bags/min

![]() Packaging dimension: L(150~300)/ W(230~450)/ H(270~450)

Packaging dimension: L(150~300)/ W(230~450)/ H(270~450)

![]() Place of Origin: CHINA.

Place of Origin: CHINA.

![]() Brand Name: IMAKO

Brand Name: IMAKO

![]() Certification: CE, ISO

Certification: CE, ISO

![]() Minimum Order Quantity: 1 SET

Minimum Order Quantity: 1 SET

![]() Trading Method: FOB/CIF/EXW Xiamen Port

Trading Method: FOB/CIF/EXW Xiamen Port

![]() Delivery Time: 90 Days

Delivery Time: 90 Days

![]() Packaging logistics: In wooded cases with fumigation finish or wrapped with plastic film.

Packaging logistics: In wooded cases with fumigation finish or wrapped with plastic film.

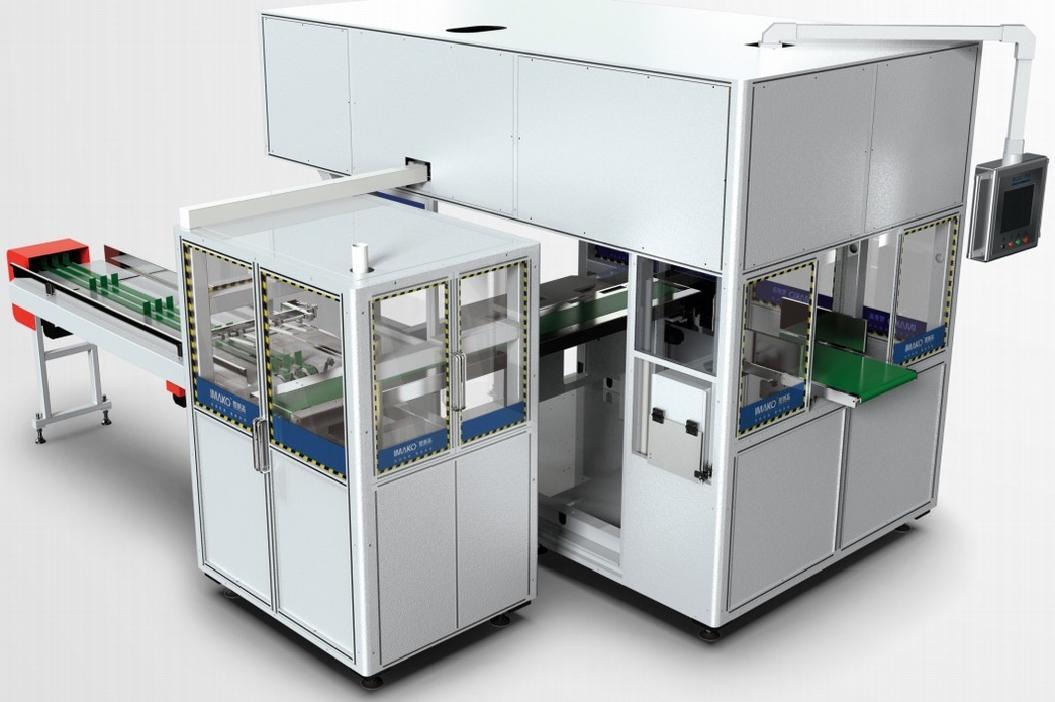

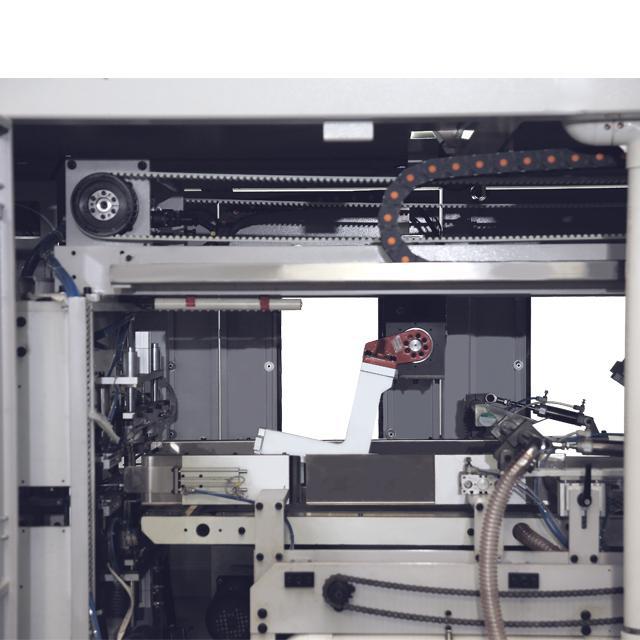

DP-C20 This machine adopts PLC and 7 shafts servo controller for drive and control unit, can realize automatic

servo control of product conveying,counting, stacking,carton catching,carton opening, product fill to carton and carton sealing.

|

Scnne Of Anr |

Bundle Packed Diaperpull Pants Eto |

Carton Storage Cuantity |

≤100 Cartons |

|

Equipment judgment mode |

Automac Single Lane Intelligent Feeding System |

Carton Seal Mod |

Seelling Machine Tape Sealing |

|

Max Production Spee |

Max. 30 Bags/min |

Machine Weight |

4000KG Scope Of Application |

|

Arrangement Type(ixrxc |

(1-2)x(1-2)×(3-4) |

Air Compression(mpa) |

≥0.6 |

|

Carton Structure |

3/5 Layes Corrugated Paper, Thickness 3-5mm, Tube Carton |

Power Supply |

380V/50HZ |

|

Carton Place Typ |

Flat Single Storage Position |

Transmission Mode |

Servo/inverter/cylinder Positioning Control |

This machine can realize bundle packed diaper autoamtic stacking and cartoning.

★Adopts servo drive for diaper separation and stacking,cartong and sealing,easy for carton size changing.

★HMI:Touch screen setting and operation.Easy and convenient for operation.

★Failure self-diagnosis alarm: The reason and location of the fault can be quickly found and display

on the touch screen to facilitate equipment maintenance.

★Adopts servo system for intelligently diaper dividing, satisfy cartoning of different products with different specification.

★ This machine can realize bundle packed diaper autoamtic stacking and cartoning.

★ Adopts servo drive for diaper separation and stacking,cartong and sealing,easy for carton size changing.

★ HMI:Touch screen setting and operation.Easy and convenient for operation.

★ Failure self-diagnosis alarm: The reason and location of the fault can be quickly found and display on the touch screen to facilitate equipment maintenance.

★ MAodn![]() pt(to)rta(s)

pt(to)rta(s)![]() e(s)t

e(s)t![]() or(m):cart(Cart)o(o)n(n)

or(m):cart(Cart)o(o)n(n) ![]() ena

ena![]() i

i![]() g(r)f

g(r)f![]() rm an(uct m)idnn(it)

rm an(uct m)idnn(it)![]() cre(i)nigco(t)

cre(i)nigco(t)![]() ,sta(av)

,sta(av)![]() ile(d) r(r)unn(unn)in(n)g.without carton or diaper.

ile(d) r(r)unn(unn)in(n)g.without carton or diaper.

★ Adopts servo system for intelligently diaper dividing, satisfy cartoning of different products with different specification.

★ Equipped with air source mangement function, fault alarm display function,servo overload protection function.

Adopts servo system for intelligently diaper dividing,satisfy cartoning of different products with different specification.

Adopts PLC cooperate with sensor to control diaper feeding and array. Use servo to control sealing and gusset unit. Has advantages of complete operation configuration, high efficiency, ...

DP-B4ODA automatic diaper packing machine is suitable to connect with the stacking unit of diaper making machine to realize automatic diaper packing....

Adopts PLC cooperate with sensor to control diaper feeding and array. Use servo to control bag filling and sealing. Has advantages of complete operation configuration, high efficiency, ...

Has advantages of complete operation configuration, high efficiency, easy to operate, wide size range, quick sizes changing, convenient maintenance, low cost in using etc....

we've seen a noticeable decrease in packaging errors. It's precise and ensures every diaper is properly sealed.Scarlett 2024-06-05

We've been using the adult diaper packing machine for months now and couldn't be happier to operate and has reduced our packaging time by half!Harper 2024-06-05

allowing us to fulfill orders faster and more efficiently.Layla 2024-06-05

It's efficient, reliable, and has significantly increased our output.Sophia 2024-06-05

Our customers have been impressed with the quality of packaging since . It gives our products a professional finish.Madison 2024-06-05