![]() Price: Negotiable

Price: Negotiable

![]() Model Number: TP-B30RY

Model Number: TP-B30RY

![]() Power: 23.7kw

Power: 23.7kw

![]() Application: Coreless Flat Roll Paper and Core/Coreless Round Roll Paper

Application: Coreless Flat Roll Paper and Core/Coreless Round Roll Paper

![]() Weight: 3400KG

Weight: 3400KG

![]() Output: 22Bag/min

Output: 22Bag/min

![]() Packaging dimension: Length (L): 240-650 Width (W): 110-210(s type110-420) Height (H): 80-150 mm

Packaging dimension: Length (L): 240-650 Width (W): 110-210(s type110-420) Height (H): 80-150 mm

![]() Place of Origin: CHINA.

Place of Origin: CHINA.

![]() Brand Name: IMAKO

Brand Name: IMAKO

![]() Certification: CE, ISO

Certification: CE, ISO

![]() Minimum Order Quantity: 1 SET

Minimum Order Quantity: 1 SET

![]() Trading Method: FOB/CIF/EXW Xiamen Port

Trading Method: FOB/CIF/EXW Xiamen Port

![]() Delivery Time: 90 Days

Delivery Time: 90 Days

![]() Packaging logistics: In wooded cases with fumigation finish or wrapped with plastic film.

Packaging logistics: In wooded cases with fumigation finish or wrapped with plastic film.

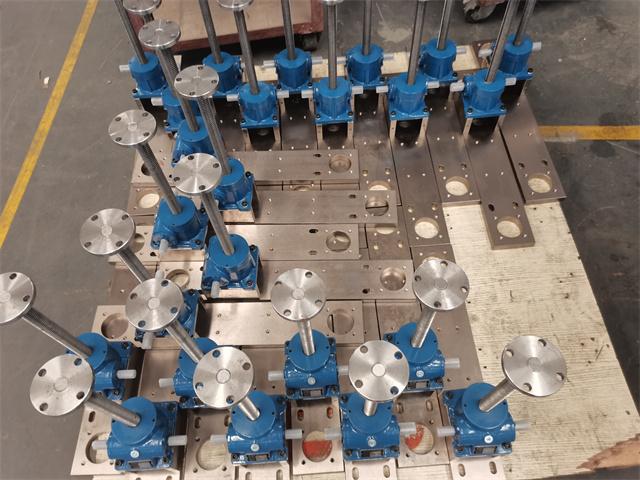

★This machine adopts PLC and 16 shafts servo movement controller for controlling unit, realize servo controlling for product conveying, flatting, counting, bag catch, bag open, tissue fill to bag and sealing.

★This machine can dual use for automatically bundle packing both coreless flat roll paper and core/coreless round roll paper. Easy to swift.

★Adopts vacuum forming mould for sealing part, ensure nice packaging effect.

★Fault self-diagnosis and alarm, can find out the faults and it’s position quality and will auto display on the touch, easy for trouble shouting and machine maintenance.

★Monitoring system: Detect both bags and paper to avid machine running without bag or without product. Will discharge the bag automatically when bag malposition. Auto stop when bag opening abnormal.

★Adopts double lanes feeding,auto roll paper flatting. Flatting degree can be adjusted freely, sharfe forming nice. Flatting roll paper and round roll paper swift can be realize by cylinder up/down controlling.

|

TP-B30RYmain parameter configuration |

|

|

Specification/Model /ltem |

TP-B30RYV、TP-B30RYM |

|

Scope of application |

Coreless flat roll paper |

|

Feeding type |

Auto double lanes feeding |

|

Design speed |

25 packs/min |

|

Stable speed |

18-22 packs/min |

|

Packaging material install structure |

Dual bag racks |

|

Bag storage qty |

≤600 |

|

Packaging style |

2x4、2×5、2×6 |

|

Machine weight(KG) |

4500 |

|

Bag style |

Pre-bag |

|

Bag material & thickness |

PE/0.04-0.05mm |

|

Air compression (MPA) |

0.6 |

|

Flow(umin) |

300 |

|

Electrical control system |

VEICHIMITSUBISHI |

|

Temp.control system |

YUDIAN |

|

Pneumatic system |

SMC/AIRTAC |

|

Servo control shaft nos |

11 |

|

Optional device |

Ink printer,thermos transfer printer |

|

Optional function |

Flat roll/round roll used packing |

Equipped with functions of bag open protection function, waste bag free stop automatic rejection, air source management, fault alarm and display, servo overload protection.overload protection.

★Adopts servos control for tissue arrangement, counting, filling preparation, tissue fill to bag, bag catching, bag conveying. This machine is easy to operate and maintain. ★Adop...

Main performance and structure features 1. Double transducer control, easy maintained, decreasing abrasion with long life. 2. human-machine operation, convenient and quick parame...

The creation of toilet paper is one of the most important inventions in the history of personal hygiene. Toilet paper making machines have made it easier for manufacturers to produce to...

When it comes to personal hygiene products, one item we cannot do without is toilet paper. The invention of the toilet paper making machine revolutionized the production of this product...

this Toilet Paper Rolls Packing Machine has streamlined our packaging process, saving us time and resourcesCamila 2024-06-05

our staff quickly learned to operate this toilet paper packing machine without extensive training.lisa 2024-06-05

design allows us to maximize space in our facility, optimizing our workflow.Hazel 2024-06-05

We've seen a noticeable improvement in our packaging efficiency since implementingNathan 2024-06-05

The durability of this toilet roll pakaging machine ensures long-term performance, delivering consistent results day after day.Harper 2024-06-05