![]() Price: Negotiable

Price: Negotiable

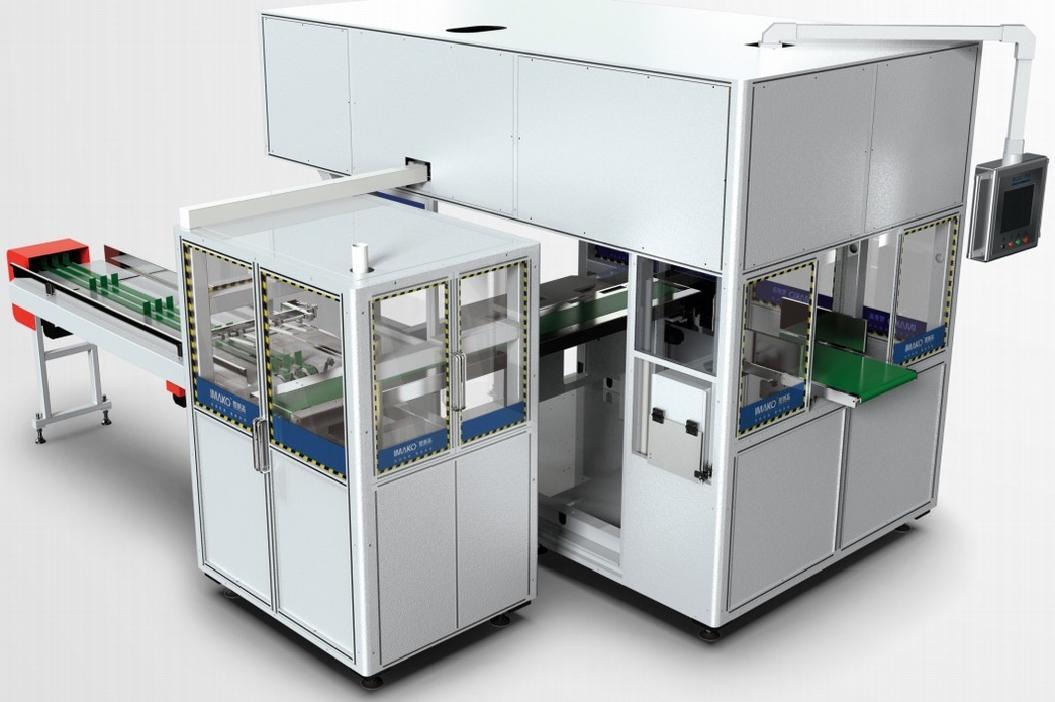

![]() Model Number: DP-C10

Model Number: DP-C10

![]() Power: 12KW

Power: 12KW

![]() Application: diaper stacking and carton packing

Application: diaper stacking and carton packing

![]() Weight: 4000kg

Weight: 4000kg

![]() Output: 10 cartons/min

Output: 10 cartons/min

![]() Packaging dimension: Length (L): 150-300 Width (W): 230-450 Height (H): 270-45 MM

Packaging dimension: Length (L): 150-300 Width (W): 230-450 Height (H): 270-45 MM

![]() Place of Origin: CHINA.

Place of Origin: CHINA.

![]() Brand Name: IMAKO

Brand Name: IMAKO

![]() Certification: CE, ISO

Certification: CE, ISO

![]() Minimum Order Quantity: 1 SET

Minimum Order Quantity: 1 SET

![]() Trading Method: FOB/CIF/EXW Xiamen Port

Trading Method: FOB/CIF/EXW Xiamen Port

![]() Delivery Time: 90 Days

Delivery Time: 90 Days

![]() Packaging logistics: In wooded cases with fumigation finish or wrapped with plastic film.

Packaging logistics: In wooded cases with fumigation finish or wrapped with plastic film.

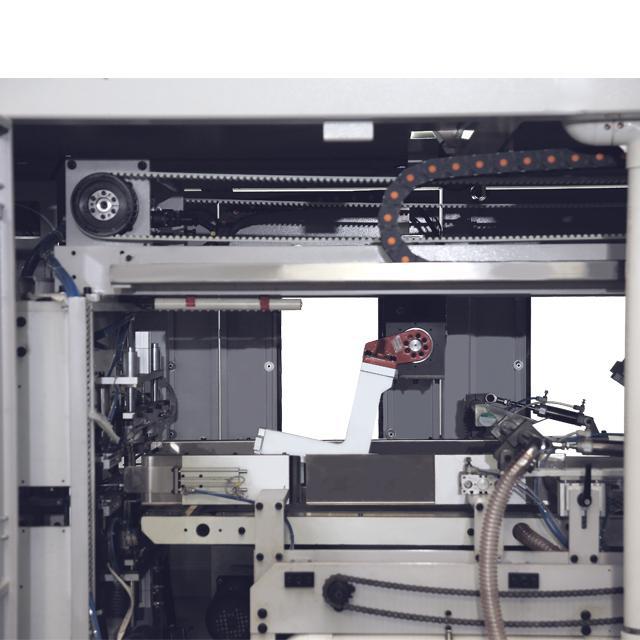

★ This machine adopts PLC and 7 shafts servo movements controller for driving and controlling unit. Product conveying, counting, stacking, carton picking, carton opening and sealing are controlled by servos.

★ This machine realizes automatically diaper stacking and carton packing.

★ Adopts servo for diaper stacking and carton sealing, convenient for carton size change over.

|

DP-C10 main parameter configuration |

||

|

Specification/Model/ ltem |

DP-C10 |

|

|

Scope of application |

Soft packed baby diaper and pull-ups |

|

|

Tissue feeding mode |

Automatic single lane intelligent feeding system |

|

|

Feeding speed |

Max. feeding speed:30 bags/min |

|

|

Array type (Layer x row x column) |

(1-2)x(1-2)x(3-4) |

See packing drawing |

|

Design speed |

12 cartons/min |

Relate to product size |

|

Stable speed |

10 cartons/min |

|

|

Percent of pass |

≥98% |

In packing range |

|

Carton structure |

3,5 layers corrugated carton.thickness 3-5mm,drum carton |

Need punch forming in advance, with fold |

★ This machine equipped with fault self-diagnosis, can trace the fault cause and display on touch, easy for machine maintenance.

★ Equips with monitoring system, can monitor if carton absence or product absence, avoid machine running without carton or product.

★ Adopts tape for carton sealing, firm and reliable,nice sealing,stably running.

★ Adopts servo control for material feeding system, intelligent material feeding. Can satisfy carton packing of different product with different specification.

★ Equipped with air source management, fault alarm and display, servo overload protection.

Adopts PLC cooperate with sensor to control diaper feeding and array. Use servo to control sealing and gusset unit. Has advantages of complete operation configuration, high efficiency, ...

DP-B4ODA automatic diaper packing machine is suitable to connect with the stacking unit of diaper making machine to realize automatic diaper packing....

The machine adopts PLC cooperates with sensors to control diaper feeding and separating....

DP-B2OD diaper packing machine is suitable for conveying and sealing of baby diaper,pull pants,adult pull pants,nursing pad etc....

It's efficient, reliable, and has significantly increased our output.Sophia 2024-06-05

allowing us to fulfill orders faster and more efficiently.Layla 2024-06-05

we've seen a noticeable decrease in packaging errors. It's precise and ensures every diaper is properly sealed.Scarlett 2024-06-05

Our customers have been impressed with the quality of packaging since . It gives our products a professional finish.Madison 2024-06-05

We've been using the adult diaper packing machine for months now and couldn't be happier to operate and has reduced our packaging time by half!Harper 2024-06-05