![]() Brand Name: IMAKO

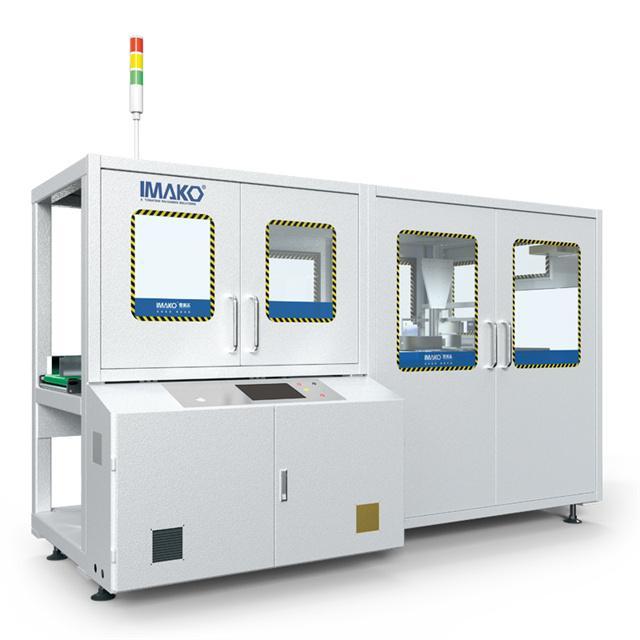

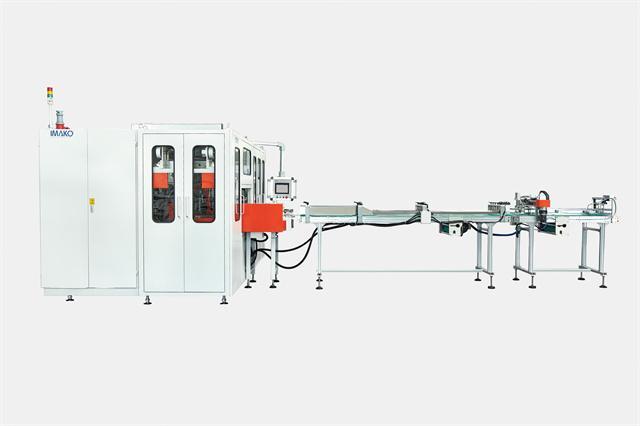

Brand Name: IMAKO

![]() Price: Negotiable

Price: Negotiable

![]() Model Number: TP-H250

Model Number: TP-H250

![]() Power: 68.52KW

Power: 68.52KW

![]() Application: Handkerchief Tissue

Application: Handkerchief Tissue

![]() Weight: 18040KG

Weight: 18040KG

![]() Output: 180Pack/min

Output: 180Pack/min

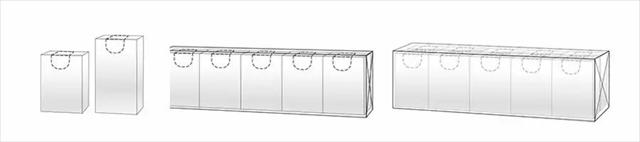

![]() Packaging dimension: Length (L): 72±2/105±2 Width (W): 53±2/53±2 Height (H): 25±2/25±2 MM

Packaging dimension: Length (L): 72±2/105±2 Width (W): 53±2/53±2 Height (H): 25±2/25±2 MM

![]() Place of Origin: CHINA.

Place of Origin: CHINA.

![]() Certification: CE, ISO

Certification: CE, ISO

![]() Minimum Order Quantity: 1 SET

Minimum Order Quantity: 1 SET

![]() Trading Method: FOB/CIF/EXW Xiamen Port

Trading Method: FOB/CIF/EXW Xiamen Port

![]() Delivery Time: 90 Days

Delivery Time: 90 Days

![]() Packaging logistics: In wooded cases with fumigation finish or wrapped with plastic film.

Packaging logistics: In wooded cases with fumigation finish or wrapped with plastic film.

|

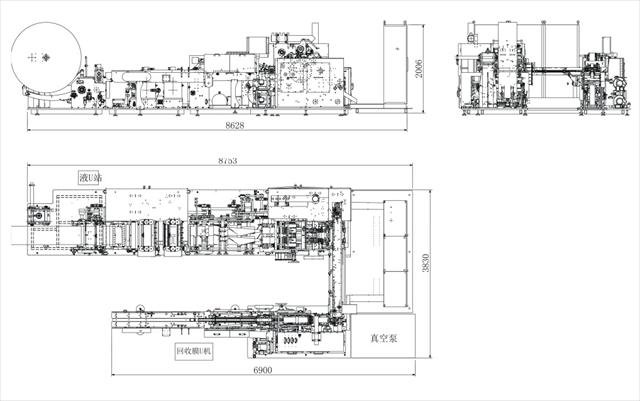

TP-H250 main parameter configuration |

||

|

Specification/Model/ ltem |

TP-H250 |

|

|

Unwinders |

Dual unwanders |

One use one spare |

|

Jumbo roll dia. |

≤1500 |

|

|

Tissue open size |

420 |

|

|

Gram weight(gCm) |

2Ply 18-20 |

|

|

3Ply 13-16 |

||

|

4Ply 12-14 |

||

|

Power supply |

380V/50Hz |

|

|

Packaging film material |

CPP、PE |

|

|

Packaging film thickness(mm) |

0.04~0.05 |

Singe pack and bundle pack need to use diflerent film material |

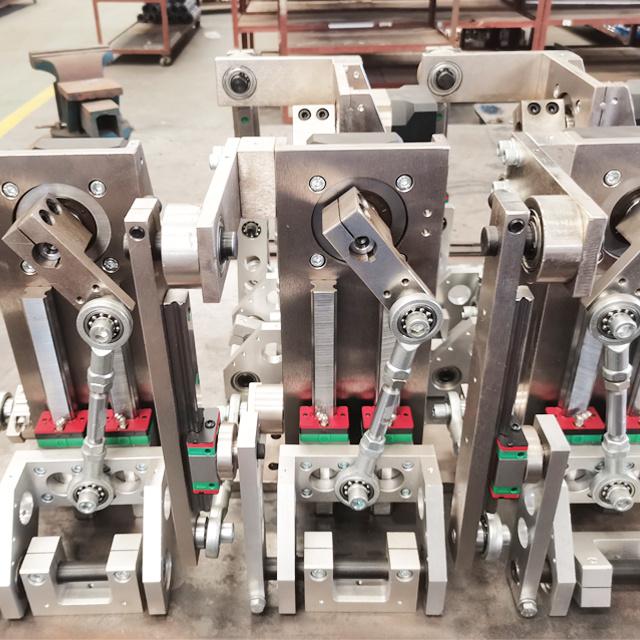

The machine combine the high qualification rate and effective productivity to one, save labor and raw material cost. Control system is completely self-contained, run stably. Use surface is positive, few and short Fold; Cutting side is smooth, no black and burr; Regular fold, derangerment is 2 mm, no inner fold. And backslash; Side embossing is symmetrical and clear, no delaminating

The machine combine the high qualification rate and effective productivity to one, save labor and raw material cost. Control system is completely self-contained, run stably....

The machine combine the high qualification rate and effective productivity to one, save labor and raw material cost. Control system is completely self-contained, run stably....

Adopts servos control for tissue arrangement, counting, tissue pushing, tissue forwarding, bag opening, tissue fill into bag. This machine is easy to operate and maintain...

TP-T300 multi servo large size facial tissue single wrapping machine is suitable for automatically packing facial tissue paper, V fold wipes, napkins or similar Non-woven fabric, dust-f...

The Folded Paper Towels Packing Machine exceeded our expectations in terms of efficiency and reliabilityMatthew 2024-06-04

This machine has significantly increased our production capacity while maintaining quality standardsCarter 2024-06-04

Our customers have commented positively on the neat and professional appearance of our packed paper towelsJoshua 2024-06-04

We've experienced a noticeable decrease in downtime since implementing this packaging solutionIsaac 2024-06-04

The compact design of the Folded Paper Towels Packing Machine saves valuable floor space in our facility.Jack 2024-06-04