<p> Tissue folding machines are an essential part of the tissue manufacturing industry. They are used to create folded tissues or paper towels that can be easily pulled out from a dispenser. These machines use cutting-edge technology to produce high-quality tissue products that meet the needs of different customers. </p>

<h2>1. The working principle of tissue folding machines</h2>

<p> Tissue folding machines work by taking a large roll of tissue paper and cutting it into smaller sections. The machine then folds each section in a specific way, depending on the type of tissue product being produced. The folded sections are then packaged in boxes or plastic bags and sent to customers. Some tissue folding machines have multiple stations for different folding patterns, which makes them more efficient and versatile. </p>

<h2>2. The importance of tissue folding machines in the tissue manufacturing industry</h2>

<p> Tissue folding machines are crucial because they automate the folding process, which saves both time and labor costs. Additionally, these machines can create a wide range of tissue products, including napkins, paper towels, and facial tissues. They also ensure consistent quality across all products, which is crucial for customer satisfaction. Since tissue products are in high demand, tissue folding machines are necessary to meet this demand and maintain a competitive edge in the industry. </p>

<h2>3. Advancements in tissue folding machine technology</h2>

<p> Over the years, tissue folding machines have undergone significant improvements in terms of efficiency, speed, and accuracy. Modern tissue folding machines use advanced control systems to ensure precise and consistent folding. They are also equipped with sensors that detect any defects in the tissue paper, which helps to avoid wastage. Additionally, some machines can switch between different folding patterns seamlessly, which further increases their versatility. With the advent of Industry 4.0, tissue folding machines are becoming even more automated, which will further reduce labor costs and increase production efficiency. </p>

<p> In conclusion, tissue folding machines are essential for the tissue manufacturing industry, as they help to automate the folding process, ensure consistent quality, and meet the high demand for tissue products. With advancements in technology, these machines will continue to play a crucial role in the industry, driving efficiency, productivity, and profitability. </p>

<p> Tissue folding machines are an essential part of the tissue manufacturing industry. They are used to create folded tissues or paper towels that can be easily pulled out from a dispenser. These machines use cutting-edge technology to produce high-quality tissue products that meet the needs of different customers. </p>

<h2>1. The working principle of tissue folding machines</h2>

<p> Tissue folding machines work by taking a large roll of tissue paper and cutting it into smaller sections. The machine then folds each section in a specific way, depending on the type of tissue product being produced. The folded sections are then packaged in boxes or plastic bags and sent to customers. Some tissue folding machines have multiple stations for different folding patterns, which makes them more efficient and versatile. </p>

<h2>2. The importance of tissue folding machines in the tissue manufacturing industry</h2>

<p> Tissue folding machines are crucial because they automate the folding process, which saves both time and labor costs. Additionally, these machines can create a wide range of tissue products, including napkins, paper towels, and facial tissues. They also ensure consistent quality across all products, which is crucial for customer satisfaction. Since tissue products are in high demand, tissue folding machines are necessary to meet this demand and maintain a competitive edge in the industry. </p>

<h2>3. Advancements in tissue folding machine technology</h2>

<p> Over the years, tissue folding machines have undergone significant improvements in terms of efficiency, speed, and accuracy. Modern tissue folding machines use advanced control systems to ensure precise and consistent folding. They are also equipped with sensors that detect any defects in the tissue paper, which helps to avoid wastage. Additionally, some machines can switch between different folding patterns seamlessly, which further increases their versatility. With the advent of Industry 4.0, tissue folding machines are becoming even more automated, which will further reduce labor costs and increase production efficiency. </p>

<p> In conclusion, tissue folding machines are essential for the tissue manufacturing industry, as they help to automate the folding process, ensure consistent quality, and meet the high demand for tissue products. With advancements in technology, these machines will continue to play a crucial role in the industry, driving efficiency, productivity, and profitability. </p>

<p>The fully automatic toilet paper making machine is a state-of-the-art technology that can produce high-quality toilet papers with minimal human intervention. The machine has revolutionized the toilet paper industry, making it possible for manufacturers to produce high volumes of toilet papers that meet the hygiene standards and consumer preferences.</p>

<h2>Improved efficiency</h2>

<p>The fully automatic toilet paper making machine has greatly improved the efficiency of the toilet paper manufacturing process. The machine can produce high volumes of toilet paper within a short period of time, reducing the production time and increasing the output. The machine is designed to handle various paper grades, ensuring that manufacturers can produce toilet paper of different qualities to cater to the diverse needs of consumers. Automated processes such as slitting, rewinding, and perforating have eliminated the need for manual intervention in the manufacturing process, further enhancing the efficiency of the machine.</p>

<h2>Enhanced product quality</h2>

<p>The fully automatic toilet paper making machine has enhanced the quality of toilet paper products. The machine ensures that the paper is rolled evenly, perforated accurately, and hygienically packaged. The machine's automated processes ensure that the toilet paper has consistent quality, including thickness, softness, and absorbency. The machine has also reduced the production of defective products, ensuring that manufacturers produce high-quality toilet papers that meet customer expectations and regulatory requirements.</p>

<h2>Improved safety</h2>

<p>The fully automatic toilet paper making machine has improved the safety of the toilet paper manufacturing process. The machine has several safety features, including automatic shutdown in case of emergencies, sensors that detect operational errors, and protective barriers that prevent accidents. The machine's automated processes have eliminated the need for workers to handle hazardous materials, reducing the risk of occupational injuries or illnesses.</p>

<p>In conclusion, the fully automatic toilet paper making machine is a game-changer in the toilet paper industry. It has improved the efficiency, product quality, and safety of the manufacturing process, enabling manufacturers to produce high volumes of toilet papers that meet customer expectations and regulatory requirements. The machine's automation has eliminated many manual processes, making the manufacturing process faster, safer, and more reliable. As technology advances, we can expect to see more innovation in the toilet paper industry, further enhancing the hygiene and comfort of our daily lives.</p>

<p>Automatic tissue paper making machines have revolutionized the way tissue paper is produced in industrial settings. These machines are highly automated and use advanced technology to streamline the production process. In this article, we will take a closer look at these machines and how they work.</p>

<h2>How Does an Automatic Tissue Paper Making Machine Work?</h2>

<p>The automatic tissue paper making machine is designed to produce large volumes of tissue paper quickly and efficiently. It uses a multi-stage process that starts with the raw materials and ends with finished products. The first stage is the pulping stage, where the raw materials such as wood chips, bamboo or recycled paper are broken down into fibers. The fibers are then cleaned, refined, and bleached to produce a pulp that is ready for use.</p>

<p>The second stage is the forming stage, where the pulp is set onto a wire mesh to form the tissue paper. The paper is then pressed between two rollers to remove excess water, and the resulting sheet is dried on a heated drum. Next comes the sizing stage, where the paper is coated with a thin layer of starch to improve its strength and absorbency. Finally, the paper is wound into rolls and packaged for distribution.</p>

<h2>The Advantages of Using an Automatic Tissue Paper Making Machine</h2>

<p>The use of automatic tissue paper making machines has been a game-changer for businesses that require high volumes of tissue paper. These machines offer several advantages over traditional production methods. For starters, they are highly automated, which means they require minimal human intervention. This not only makes the production process more efficient but also helps to reduce labor costs.</p>

<p>In addition, automatic tissue paper making machines offer greater precision and consistency in the quality of the finished product. They are equipped with sensors and software that monitor and control the various stages of the production process, ensuring that the paper meets the required standards. This reduces the likelihood of defective products, which in turn helps to improve customer satisfaction.</p>

<h2>Considerations When Choosing an Automatic Tissue Paper Making Machine</h2>

<p>When choosing an automatic tissue paper making machine, there are several factors to consider. The first is the output capacity of the machine. Businesses need to select a machine that can meet their production needs while also being cost-effective.</p>

<p>The second factor to consider is the quality of the finished product. Consider machines that offer high precision and consistency in terms of paper size, weight, and strength. This will ensure that the end products meet the required quality standards.</p>

<p>Finally, consider the maintenance requirements and ongoing costs of the machine. Opt for a machine that has low maintenance requirements and offers good value for money. This will help to ensure that the machine remains cost-effective over the long term.</p>

<h2>Conclusion</h2>

<p>In conclusion, automatic tissue paper making machines have revolutionized the way tissue paper is produced in industrial settings. They offer several advantages over traditional production methods, including greater efficiency, precision, and consistency. When choosing an automatic tissue paper making machine, businesses need to consider factors such as output capacity, product quality, and maintenance requirements. By doing so, they can select a machine that meets their needs and helps to improve their bottom line.</p>

![]() Price: Negotiable

Price: Negotiable![]() Model Number: 280

Model Number: 280![]() Power: 12KW

Power: 12KW![]() Application: tissue packaging

Application: tissue packaging![]() Weight: 3000kgs

Weight: 3000kgs![]() Output: 50p/min

Output: 50p/min![]() Packaging dimension: TBN

Packaging dimension: TBN![]() Place of Origin: CHINA.

Place of Origin: CHINA.![]() Brand Name: IMAKO

Brand Name: IMAKO![]() Certification: CE, ISO

Certification: CE, ISO![]() Minimum Order Quantity: 1 SET

Minimum Order Quantity: 1 SET![]() Trading Method: FOB/CIF/EXW Xiamen Port

Trading Method: FOB/CIF/EXW Xiamen Port![]() Delivery Time: 90 Days

Delivery Time: 90 Days![]() Packaging logistics: In wooded cases with fumigation finish or wrapped with plastic film.

Packaging logistics: In wooded cases with fumigation finish or wrapped with plastic film.

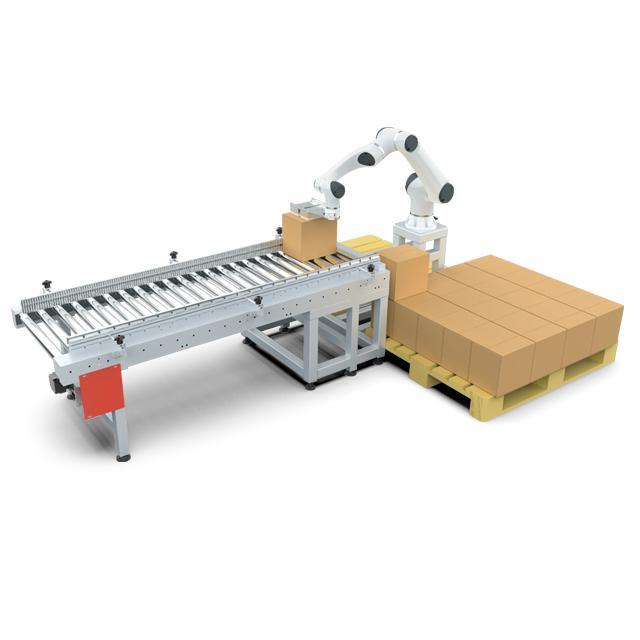

The durability and reliability of the robot palletizer have exceeded our expectations, resulting in minimal downtime.James 2024-06-06

Our team loves how easy it is to program and customize the robot palletizer to fit our unique needs.Ethan 2024-06-06

increasing efficiency by at least 30%.Victoria 2024-06-06

With the robotic palletizer, we've seen a significant reduction in errors, leading to smoother logistics.Aiden 2024-06-06

we've been able to reallocate labor resources to more value-added tasks.Lucas 2024-06-06