![]() Price: Negotiable

Price: Negotiable

![]() Model Number: RP-10

Model Number: RP-10

![]() Power:

Power:

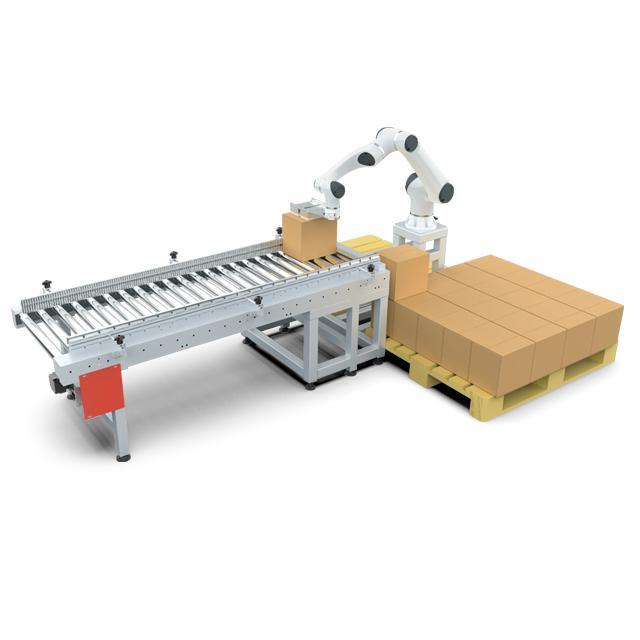

![]() Application: boxes and bags

Application: boxes and bags

![]() Weight: 20 Kg

Weight: 20 Kg

![]() Output: Stack up to 8 box/minute

Output: Stack up to 8 box/minute

![]() Packaging dimension: Generally up to 1650mm

Packaging dimension: Generally up to 1650mm

![]() Place of Origin: CHINA.

Place of Origin: CHINA.

![]() Brand Name: IMAKO

Brand Name: IMAKO

![]() Certification: CE, ISO

Certification: CE, ISO

![]() Minimum Order Quantity: 1 SET

Minimum Order Quantity: 1 SET

![]() Trading Method: FOB/CIF/EXW Xiamen Port

Trading Method: FOB/CIF/EXW Xiamen Port

![]() Delivery Time: 90 Days

Delivery Time: 90 Days

![]() Packaging logistics: In wooded cases with fumigation finish or wrapped with plastic film.

Packaging logistics: In wooded cases with fumigation finish or wrapped with plastic film.

* Safety and stable

It can directly work side by side with human without using safety fence for isolation;

Support level 10 collision detection and sensor safety detection,with high reliability and safety;

Provides 16 secure I/O interfaces to ensure that security functions are not lost when a single fault occurs.

The terminal does not fall when power off, and the product is safe and stable;

* Flexible production

Quick switching of various functional scenarios, flexible production can be realized by human-machine collaboration, dual-machine collaboration, and multi-machine collaboration;

The investment cost is recovered in an average of 6-12 months;

|

RP-10 main parameter configuration |

|

|

Max. stack height * |

The maximum stackable height is 2100mm (including tray); |

|

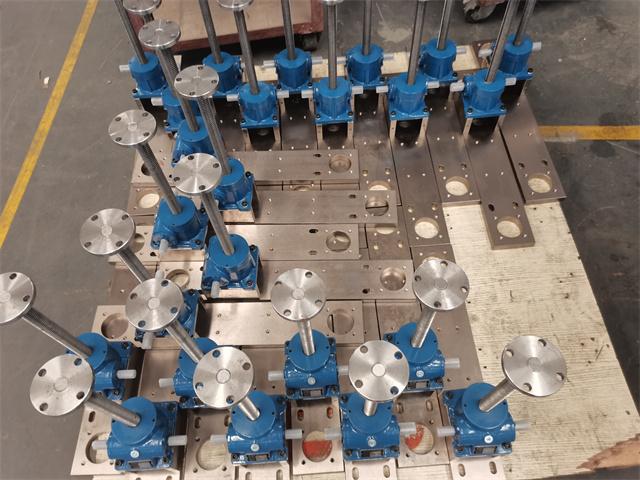

Max. allowable load |

20kg |

|

Fastest stack speed |

Stack up to 8 box/minute |

|

Co-working radius |

Max. co-working diameter:1600mm |

|

Security function |

16 working unit level safety functions, safety level PL=d |

|

Demonstrator |

10.1 inch capacitive touch screen with emergency stop and three-stage switch, |

|

IP rating |

Robot arm IP54, demonstrator IP65 |

|

Interface |

Supports multiple safety inputs and outputs, |

|

Software |

Offline editing and 3D simulation: TMstudio Palletizing Wizard |

|

Light status |

When powered on normally, the indicator light is always red; When powered off, the indicator light is off |

This machine is suitable for stacking boxes and bags in its specifications range.

Scope of application-Carton packing for single pack facial tissue...

Scope of application - Carton packing for single pack and bundle pack facial tissue . Compressed Air (mpa) -Air source≥0.6MPA,Air flow: 300L/min...

Packing style -The top side should allow vacuum suction...

Max.Stacking Height 2100(withPallet),normally 1650mml with Pallet...

* Safety and stable It can directly work side by side with human withoutusing safety fence for isolation; Support level 10 collision detection and sensor safety detection,with high rel...

With the robotic palletizer, we've seen a significant reduction in errors, leading to smoother logistics.Aiden 2024-06-06

increasing efficiency by at least 30%.Victoria 2024-06-06

The durability and reliability of the robot palletizer have exceeded our expectations, resulting in minimal downtime.James 2024-06-06

Our team loves how easy it is to program and customize the robot palletizer to fit our unique needs.Ethan 2024-06-06

we've been able to reallocate labor resources to more value-added tasks.Lucas 2024-06-06