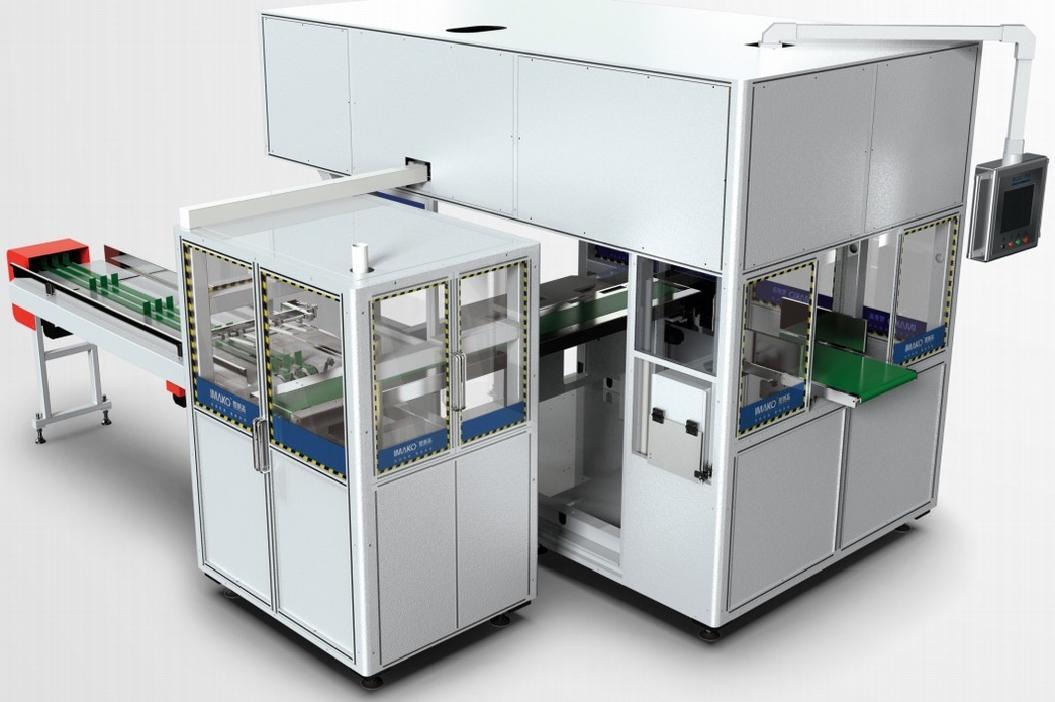

Author:IMAKO Tissue MachineFROM:Toilet Paper Machine Manufacturer TIME:2023-07-07

The applications of tissue paper making small machines have become increasingly widespread in various industries. These machines offer a cost-effective and efficient solution for producing tissue papers in smaller quantities. In this article, we will explore the different applications of these machines and the benefits they bring.

One of the primary applications of tissue paper making small machines is in small-scale production facilities. These machines are ideal for businesses that require a lower volume of tissue paper production. They allow these businesses to produce their own tissue papers in-house, eliminating the need for outsourcing or purchasing from larger manufacturers.

Small-scale production using these machines offers several advantages. Firstly, it allows businesses to have better control over the quality of their tissue papers, ensuring that they meet their specific requirements. Secondly, it provides flexibility in terms of customization, enabling businesses to create unique and branded tissue papers that align with their marketing strategies. Lastly, small-scale production reduces storage and inventory costs, as businesses can produce tissue papers on-demand.

Tissue paper making small machines are also widely used in the production of specialty tissue papers. Specialty tissue papers refer to those that have specific characteristics or functionalities beyond regular tissue papers. Some examples include colored tissue papers, scented tissue papers, and embossed tissue papers.

These machines enable manufacturers to easily incorporate various additives and enhancements into the tissue papers during the production process. For instance, the addition of colors or fragrances can be achieved through special dyeing or perfuming techniques. Embossing patterns onto the tissue papers can also be done using these machines, creating a more tactile and visually appealing product.

Specialty tissue papers often find applications in the gift wrapping, crafts, and hospitality industries. They add a touch of uniqueness and personalization to these products and enhance the overall customer experience.

Tissue paper making small machines play a crucial role in research and development activities related to tissue paper production. These machines provide a convenient and cost-effective way for researchers and scientists to test and experiment with different raw materials, manufacturing processes, and product formulations.

Researchers can use these machines to produce small batches of tissue papers for testing purposes. By varying the parameters such as the type of fibers, the pulp concentration, or the drying conditions, they can evaluate the impact on the paper's strength, absorbency, softness, and other properties. This information is invaluable for optimizing the production process and developing high-quality tissue papers.

In conclusion, tissue paper making small machines have a wide range of applications and benefits. They enable small-scale production, facilitate the production of specialty tissue papers, and support research and development efforts. With these machines, businesses and researchers can enjoy greater control, flexibility, and cost-efficiency in tissue paper production.