Author:IMAKO Tissue MachineFROM:Toilet Paper Machine Manufacturer TIME:2023-07-19

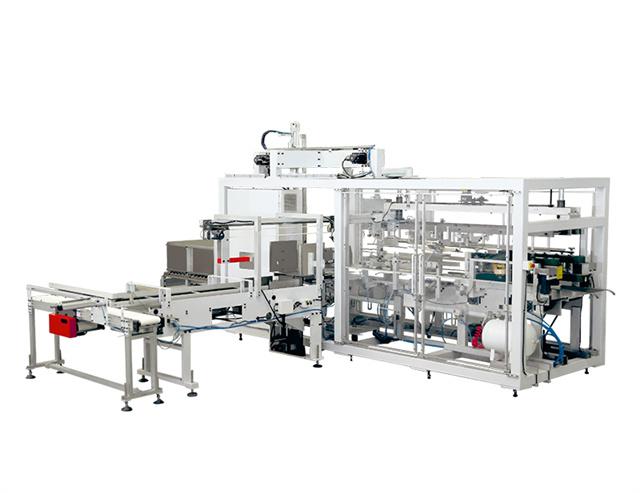

The efficient usage of tissue paper bag making machine is crucial in the manufacturing industry. With the increasing demand for eco-friendly alternatives to plastic bags, the tissue paper bag making machine has become a popular choice. This article will explore the various ways to maximize the efficiency of this machine, ultimately leading to higher productivity and cost-effectiveness.

One of the key factors in ensuring efficient usage of the tissue paper bag making machine is to optimize its settings. This includes adjusting the machine's speed, temperature, and tension control according to the specific requirements of the production process. By fine-tuning these settings, manufacturers can minimize downtime, reduce material waste, and achieve optimal production output.

To ensure a smooth and uninterrupted operation, regular maintenance and inspection of the tissue paper bag making machine are vital. This involves cleaning and lubricating the machine components, checking for any worn-out parts, and replacing them promptly. Additionally, routine inspection helps identify potential issues before they escalate, preventing costly breakdowns and production delays.

The efficiency of the tissue paper bag making machine also relies on the skills and knowledge of the operators. Providing comprehensive training programs to employees can enhance their understanding of the machine's operation, troubleshooting techniques, and safety precautions. Well-trained operators can effectively handle any issues that arise, minimize errors, and maximize the machine's performance.

In conclusion, efficient usage of the tissue paper bag making machine is essential for manufacturers to meet the growing demand for environmentally friendly packaging options. By optimizing machine settings, conducting regular maintenance, and enhancing employee skills, companies can improve production efficiency, reduce costs, and contribute to a sustainable future.