Author:IMAKO Tissue MachineFROM:Toilet Paper Machine Manufacturer TIME:2023-09-05

Tissue paper is an essential product in our daily lives, used for a variety of purposes such as personal hygiene, cleaning, and crafting. To meet the increasing demand for tissue paper, many companies have turned to automated machines for production. One such machine that has gained popularity is the semi-automatic tissue paper making machine. This article will explore the benefits and utilization of this machine in the tissue paper manufacturing industry.

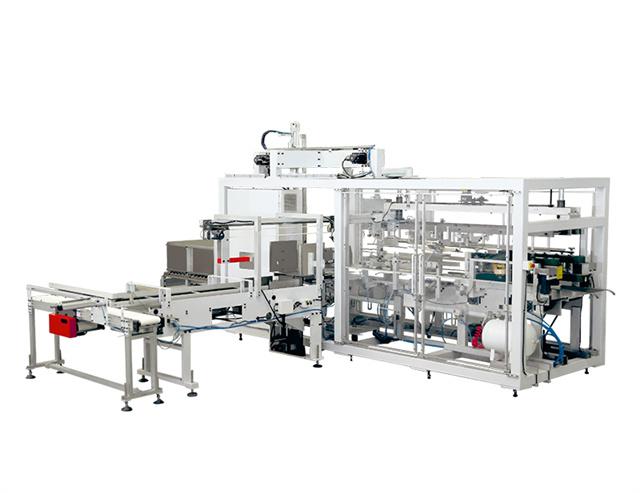

The semi-automatic tissue paper making machine offers enhanced efficiency and productivity compared to traditional manual methods. With automated processes for unwinding, embossing, cutting, and folding, the machine can produce tissue paper at a much faster rate. Additionally, it eliminates the need for manual labor, reducing the chances of human error and increasing overall productivity.

Furthermore, the machine's advanced features enable easy adjustments for different paper sizes, thicknesses, and folds. This versatility allows manufacturers to cater to various customer demands efficiently. The consistent quality of the tissue paper produced by the machine also ensures customer satisfaction, enhancing the reputation and competitiveness of the company.

Utilizing a semi-automatic tissue paper making machine is not only cost-effective but also environmentally friendly. The automated production process reduces the consumption of resources, such as energy and water, compared to manual production. It also minimizes waste by optimizing the use of raw materials and ensuring precise cuts and folds.

Moreover, the machine's efficient production capabilities result in higher output with fewer resources, reducing overall production costs. This cost-effectiveness allows manufacturers to offer competitive prices to customers while maintaining profitability. Additionally, the machine's eco-friendly nature aligns with the growing global concern for sustainable practices, attracting environmentally conscious consumers.

The semi-automatic tissue paper making machine is designed to provide operational convenience and safety. Its user-friendly interface and controls simplify the production process, enabling operators to easily set and monitor parameters such as paper tension, embossing patterns, and cutting dimensions. The intuitive design reduces the learning curve, allowing new operators to quickly adapt and perform efficiently.

Furthermore, the machine incorporates various safety features to ensure the well-being of operators and prevent accidents. Emergency stop buttons, protective barriers, and advanced sensors contribute to a safe working environment. The reduced reliance on manual labor also decreases the risk of injuries associated with repetitive tasks, improving workplace safety.

In conclusion, the utilization of a semi-automatic tissue paper making machine brings numerous benefits to the tissue paper manufacturing industry. Its enhanced efficiency, cost-effectiveness, and eco-friendly nature make it an ideal choice for companies aiming to meet the growing demand for tissue paper. Moreover, the machine's operational convenience and safety features provide a favorable working environment for operators. By embracing this advanced technology, manufacturers can enhance productivity, reduce costs, and contribute to a sustainable future.