![]() Price: Negotiable

Price: Negotiable

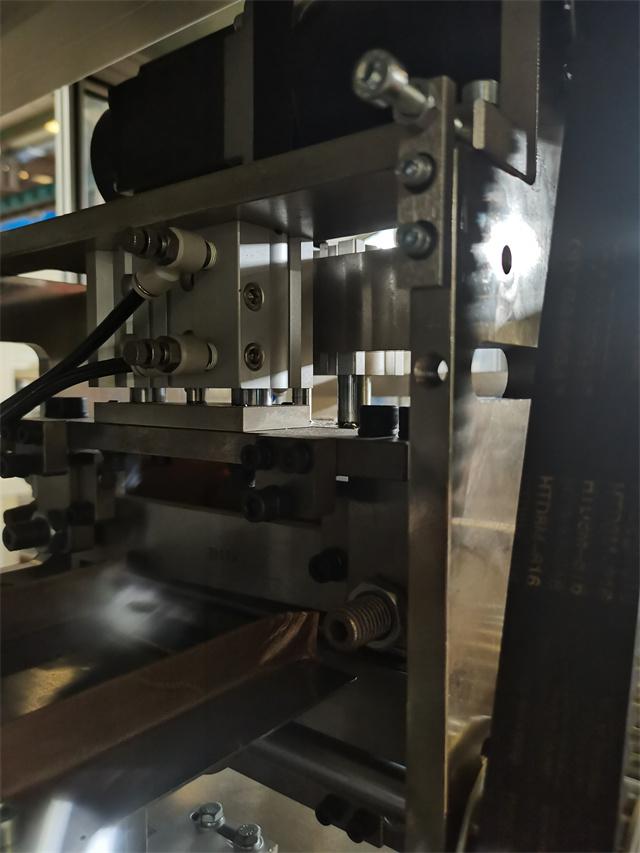

![]() Model Number: TP-T180

Model Number: TP-T180

![]() Power: 12KW,380V/50Hz

Power: 12KW,380V/50Hz

![]() Application: Single Tissue Wrapping

Application: Single Tissue Wrapping

![]() Weight: 3000KG

Weight: 3000KG

![]() Output: 100Pack/min

Output: 100Pack/min

![]() Packaging dimension: Length (L): 95-210 Width (W): 80-115 Height (H): 30-100

Packaging dimension: Length (L): 95-210 Width (W): 80-115 Height (H): 30-100

![]() Place of Origin: CHINA.

Place of Origin: CHINA.

![]() Brand Name: IMAKO

Brand Name: IMAKO

![]() Certification: CE, ISO

Certification: CE, ISO

![]() Minimum Order Quantity: 1 SET

Minimum Order Quantity: 1 SET

![]() Trading Method: FOB/CIF/EXW Xiamen Port

Trading Method: FOB/CIF/EXW Xiamen Port

![]() Delivery Time: 90 Days

Delivery Time: 90 Days

![]() Packaging logistics: In wooded cases with fumigation finish or wrapped with plastic film.

Packaging logistics: In wooded cases with fumigation finish or wrapped with plastic film.

Tissue Packaging Machine Specification

|

Max.Work Speed |

100Pack/min |

|

|

Total Power |

12KW |

|

|

Pack Range(mm) |

Length (L): 95-210 |

|

|

Width (W): 80-115(Extension150) |

||

|

Height (H): 30-100(Exceeded size can be customized) |

||

|

Tissue sorting mode |

Auto intelligent tissue sorting |

4 sections intelligent soft tissue feeding mode |

|

Design speed |

110packs/min |

relate to product size |

|

Stable speed |

100packs/min |

relate to product size |

|

Size mould |

3sets |

Product sizes are |

|

provide by buyer |

||

|

Machine weight(KG) |

3000 |

|

|

Packaging material |

CPP, PE film |

|

|

Film thickness(mm) |

0.035-0.05 |

|

|

Max. film roll dia(mm) |

500 |

|

|

Film core dia.(mm) |

76 |

international standard |

|

Max. film roll width(mm) |

340 |

|

|

Compressed air(MPA) |

Air source:≥0.5 |

Buyer prepare |

|

Power supply |

380V/50Hz |

According to |

|

national standard |

||

|

Adaptive voltage change |

0.9 |

According to |

|

national standard |

||

|

I/O input(VDC) |

24 |

Electricity control system |

|

control loop input |

||

|

I/O output(VDC) |

24 |

Electricity control system |

|

control loop output |

||

|

Movement control mode |

3 servo shafts |

Electronic CAM |

|

positioning control |

movement curve |

|

|

Main transmission mode |

20 crmnti mechanical cam +electrical cam |

|

|

Color and craft |

Grey, static spray paint craft |

|

|

Packing style |

3D wrapping |

Even heat sealing on film overlap parts |

|

Perforation option |

Straight line perforation |

Alternative |

|

Perforation option |

Oval shape perforation |

Alternative |

The tissue paper industry has been steadily growing, and it's no surprise that tissue making machines have become a crucial part of this industry. A tissue making machine is a piece of industrial equipment that is used to manufacture various types of tissue paper products. From facial tissues to toilet paper rolls, these machines are able to produce a wide range of products that are essential for daily life.

Tissue making machines use a range of raw materials such as pulp, recycled paper, water, and chemicals to create tissue paper in large rolls. The process typically involves several steps, including pulping, diluting, refining, cleaning, and drying. Once the tissue paper has been produced, it can be cut and packaged into different sizes and shapes according to customer specifications. Some machines are capable of producing thousands of rolls of tissue paper per hour, making them highly efficient for both small and large-scale production facilities.

One of the main advantages of tissue making machines is their ability to produce tissue paper products in a cost-effective manner. These machines are designed to streamline the entire production process, which helps reduce labor costs and increase production efficiency. Additionally, the use of automation technology ensures that the quality of the tissue paper products remains consistent throughout the production cycle. This means that customers receive high-quality products that are made to their exact specifications, every single time.

The demand for tissue paper products is only expected to grow in the coming years, and this means that tissue making machines will continue to play a critical role in the industry. In fact, advancements in technology are helping to make these machines even more efficient and cost-effective. For instance, some manufacturers are now using artificial intelligence (AI) and machine learning algorithms to optimize the production process and reduce waste. This not only helps reduce costs but also enhances the sustainability of the production process.

In conclusion, tissue making machines are essential for the tissue paper industry and have helped drive its growth in recent years. With the continued advancement of technology, these machines will only become more efficient and cost-effective, further enhancing their importance for the industry as a whole.

Application of automatic facial tissue single pack machine.

Automatic Facial Tissue Single Packing Machine is specialized type of packaging machine which can pack facial tissue, V fold hand towel paper and napkin.

Advantages of automatic facial tissue single pack machine.

1、Simple operation, safe and reliable.

2、Saving labor cost and improving production efficiency.

3、reliable packaging quality, to ensure product quality

4、Alarm function to improve packaging efficiency.

With the promotion and application of Kleenex single pack machine, baby care, women's skin care use of wipe paper can also be packaged with tissue single packing machine, in order to respond to the trend of consumers pay more and more attention and concern about the quality of household paper products.

One significant advantage of incorporating an automatic tissue paper machine into your production process is that it increases productivity. Unlike traditional methods that require huma...

DP-T55 This machine is suitable for automatically packing cotton tissue,facial tissue and wet wipes....

TP-T450 multi servo high spped facial tissue single wrapping machine is suitable for automatically packing facial tissue paper, V fold wipes, napkins or similar Non-woven fabric, dust-f...

This machine adopts PLC and 3 shafts servo movement controller for controlling unit, realize servo controlling for paper feeding, distribution, arrangement, catch and carton open, filli...

Our experience with the Tissues Packing Machine has been outstanding.Leah 2024-06-06

tissues machine has greatly improved our production process. It's a game-changer for our business.Ella 2024-06-06

We couldn't be happier with the Tissues Packing Machine. It's reliable, easy to use, and has increased our output significantly.Chloe 2024-06-06

This machine has exceeded our expectations. The quality of the packaging is top-notch, and it has helped us save time and resources.Riley 2024-06-06

It's user-friendly and has boosted our productivity.Isabella 2024-06-06