Author:IMAKO Tissue MachineFROM:Toilet Paper Machine Manufacturer TIME:2023-09-04

Utilization of paper tissue manufacturing machine is an essential aspect of the paper tissue industry. As technology has advanced, these machines have become more efficient and capable of producing high-quality tissue products. This article will explore the various ways in which paper tissue manufacturing machines are utilized, including their role in increasing productivity, reducing costs, and ensuring product quality.

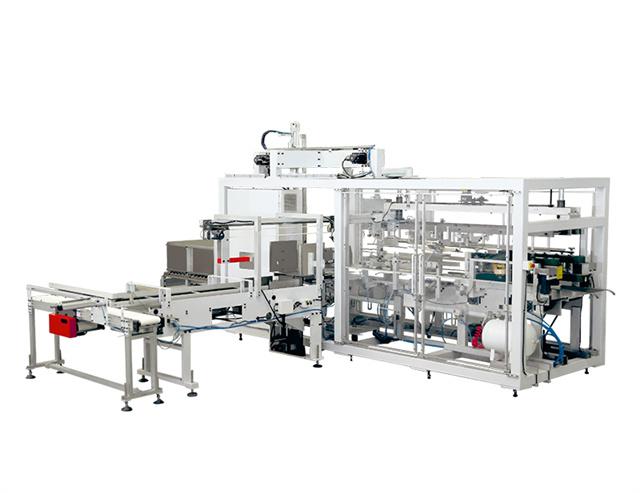

One of the primary advantages of utilizing paper tissue manufacturing machines is the significant increase in productivity. These machines are equipped with advanced automation systems that can handle various tasks simultaneously, reducing the need for manual labor. The machines can automatically feed raw materials, process them into tissue paper, and package the finished products. This automation streamlines the production process and allows manufacturers to produce a larger volume of tissue paper in a shorter period. Additionally, the machines can operate continuously without breaks, further enhancing productivity.

The utilization of paper tissue manufacturing machines also leads to substantial cost reduction for manufacturers. Firstly, the automation of various processes reduces the need for a large workforce, decreasing labor costs. Moreover, the machines are designed to minimize material wastage by precisely controlling the cutting and shaping of tissue paper. This eliminates unnecessary waste and ensures that every piece of paper is optimally utilized. Additionally, efficient energy usage and maintenance protocols result in lower operational costs. Overall, the utilization of these machines enables manufacturers to produce tissue paper at a lower cost, making their products more competitive in the market.

Paper tissue manufacturing machines play a crucial role in ensuring the quality of tissue paper products. The machines are equipped with advanced sensors and monitoring systems that continuously monitor and regulate the production process. This ensures that the tissue paper meets the required standards in terms of thickness, texture, and strength. The automation of processes also reduces the risk of human error, resulting in consistently high-quality products. Moreover, the machines can be programmed to accommodate various customization options, such as embossing or patterned designs, allowing manufacturers to cater to different customer preferences and market demands.

In conclusion, the utilization of paper tissue manufacturing machines offers numerous benefits to the tissue paper industry. These machines increase productivity by automating processes and enabling continuous operation. They also contribute to cost reduction through labor and material savings. Additionally, these machines play a vital role in ensuring consistent product quality by utilizing advanced monitoring and customization capabilities. As technology continues to advance, it is expected that paper tissue manufacturing machines will become even more efficient and versatile, further enhancing the industry's productivity and competitiveness.