![]() Price: Negotiable

Price: Negotiable

![]() Model Number: TF-1500

Model Number: TF-1500

![]() Power:

Power:

![]() Application: Tissue Paper,V Fold Napkins, Non-Woven Fabric

Application: Tissue Paper,V Fold Napkins, Non-Woven Fabric

![]() Weight:

Weight:

![]() Output:

Output:

![]() Packaging dimension:

Packaging dimension:

![]() Place of Origin: CHINA.

Place of Origin: CHINA.

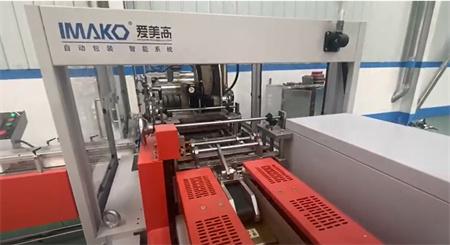

![]() Brand Name: IMAKO

Brand Name: IMAKO

![]() Certification: CE, ISO

Certification: CE, ISO

![]() Minimum Order Quantity: 1 SET

Minimum Order Quantity: 1 SET

![]() Trading Method: FOB/CIF/EXW Xiamen Port

Trading Method: FOB/CIF/EXW Xiamen Port

![]() Delivery Time: 90 Days

Delivery Time: 90 Days

![]() Packaging logistics: In wooded cases with fumigation finish or wrapped with plastic film.

Packaging logistics: In wooded cases with fumigation finish or wrapped with plastic film.

|

TF-1500-2050 main parameter configuration |

||

|

Scope of application |

tissue paper,V Fold napkins, non-woven fabric |

|

|

Separator |

Servo drive |

|

|

Jumbo roll width (mm) |

1500~2050 |

|

|

Jumbo roll Max size range (mm) |

diameter:1500,width:2050 |

|

|

Choice of paper tissue folding size (unfold) |

170/175/180/190 |

Special size please indicate |

|

Standard unreeling stand |

2 group |

Additional items need to be provided in advance |

|

Embossing unit |

Ordinary edge embossing roll, four edge embossing roll, steels/ rubber/ wooden embossing roll |

|

|

Compressed air(MPA) |

Provided by buyer |

|

|

Layer of jumbo roll |

2、3、4、5 |

|

|

Mechanical driving |

Six servo shafts drive control |

|

|

Options |

Grinding unit、Rolling over unit、 Ultrasonic spray humidification unit、Jumbo roll back stand unit |

|

|

Count setting |

Touch screen Settings |

|

★ Adopts servos control for tissue arrangement, counting, stacking, tissue fill to bag, bag catching, bag conveying, bag opening and seal parts, This machine is easy to operation and ...

TF-1500-2050 main parameter configuration Scope of application tissue paper,V Fold napkins, non-woven fabric Separator Servo drive Jumbo roll wid...

1.TP-T450A multi servo high spped facial tissue single wrapping machine is suitable for automatically packing facial tissue paper, V fold wipes, napkins or similar Non-woven fabric, dus...

Finished Product ★Maximum stable packing speed of roll paper with core: 200 rolls/min ★Maximum stable packing speed of coreless roll paper: 150 rolls/min ★Can realize length ch...

We appreciate the user-friendly interface and ease of operation of the Facial Tissue Making Machine.Addison 2024-06-06

This machine has significantly increased our production output while maintaining consistent quality.Mila 2024-06-06

The durability of this machine is impressive, it has been running smoothly without any major issues.Ava 2024-06-06

The Facial Tissue Making Machine exceeded our expectations in terms of efficiency and reliability.Nora 2024-06-06

we've been able to meet the growing demand for facial tissue products without any hassle.Hunter 2024-06-06