![]() Price: Negotiable

Price: Negotiable

![]() Model Number: 320REM

Model Number: 320REM

![]() Power: 12KW

Power: 12KW

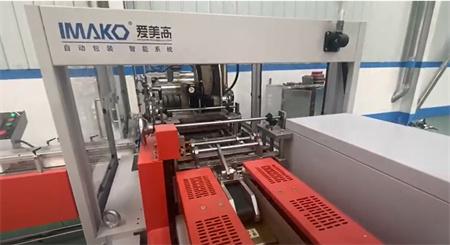

![]() Application: toilet paper packing machine

Application: toilet paper packing machine

![]() Weight: 3000kgs

Weight: 3000kgs

![]() Output: 50p/min

Output: 50p/min

![]() Packaging dimension: TBN

Packaging dimension: TBN

![]() Place of Origin: CHINA.

Place of Origin: CHINA.

![]() Brand Name: IMAKO

Brand Name: IMAKO

![]() Certification: CE, ISO

Certification: CE, ISO

![]() Minimum Order Quantity: 1 SET

Minimum Order Quantity: 1 SET

![]() Trading Method: FOB/CIF/EXW Xiamen Port

Trading Method: FOB/CIF/EXW Xiamen Port

![]() Delivery Time: 90 Days

Delivery Time: 90 Days

![]() Packaging logistics: In wooded cases with fumigation finish or wrapped with plastic film.

Packaging logistics: In wooded cases with fumigation finish or wrapped with plastic film.

★Maximum stable packing speed of roll paper with core: 200 rolls/min

★Maximum stable packing speed of coreless roll paper: 150 rolls/min

★Can realize length changing from 80-220mm by setting on touch screen directly.

★Standard functions equipped: Inching function, line function,diameter error detection and alarm function, length error detection and alarm function, film stop feeding when no material function

* Automatic open / close of fin seal roller

* Film feeding stops when there is no tissue roll

★TP-R220 automatic single roll paper wrapping machine is suitable for auto packing core/coreless toilet paper rolls and kitchen tissue rolls.

Finished Product ★Maximum stable packing speed of roll paper with core: 200 rolls/min ★Maximum stable packing speed of coreless roll paper: 150 rolls/min ★Can realize length ch...

The toilet paper roll manufacturing machine is an essential piece of equipment in the production of toilet paper rolls. It has revolutionized the toilet paper industry by making it poss...

TF-1500-2050 main parameter configuration Scope of application tissue paper,V Fold napkins, non-woven fabric Separator Servo drive Jumbo roll wid...

★ Adopts servos control for tissue arrangement, counting, stacking, tissue fill to bag, bag catching, bag conveying, bag opening and seal parts, This machine is easy to operation and ...

We appreciate the user-friendly interface and ease of operation of the Facial Tissue Making Machine.Addison 2024-06-06

The durability of this machine is impressive, it has been running smoothly without any major issues.Ava 2024-06-06

The Facial Tissue Making Machine exceeded our expectations in terms of efficiency and reliability.Nora 2024-06-06

we've been able to meet the growing demand for facial tissue products without any hassle.Hunter 2024-06-06

This machine has significantly increased our production output while maintaining consistent quality.Mila 2024-06-06