![]() Price: Negotiable

Price: Negotiable

![]() Model Number: TP-B30T

Model Number: TP-B30T

![]() Power: 18KW

Power: 18KW

![]() Application: Facial tissue machine,

Application: Facial tissue machine,

![]() Weight: 1800kg

Weight: 1800kg

![]() Output: 21 bundles/min

Output: 21 bundles/min

![]() Packaging dimension: L(180-500)×W(120-420)×H(85-100)mm

Packaging dimension: L(180-500)×W(120-420)×H(85-100)mm

![]() Place of Origin: CHINA.

Place of Origin: CHINA.

![]() Brand Name: IMAKO

Brand Name: IMAKO

![]() Certification: CE, ISO

Certification: CE, ISO

![]() Minimum Order Quantity: 1 SET

Minimum Order Quantity: 1 SET

![]() Trading Method: FOB/CIF/EXW Xiamen Port

Trading Method: FOB/CIF/EXW Xiamen Port

![]() Delivery Time: 90 Days

Delivery Time: 90 Days

![]() Packaging logistics: In wooded cases with fumigation finish or wrapped with plastic film.

Packaging logistics: In wooded cases with fumigation finish or wrapped with plastic film.

|

TP-B30T main parameter configuration |

|

|

Scope of application |

Single pack facial tissue |

|

Packing style |

1x3、1x4、1x5、1x6 2x3、2x4、2x5、2x6 3x3、3x4、3x5、3x6 |

|

Bag install mode |

Dual bag racks |

|

Bag storage quantity |

≤ 300/bags |

|

Machine weight (KG) |

1800 |

|

Machine size |

L3355 *W1580 *H1738 |

|

Bag type |

CPP、PE |

|

Compressed air (mpa) |

Air source≥0.6 Air flow≥300L / min |

|

Power supply |

308V / 50HZ |

|

Sealing mode |

Heating tube heating to seal |

|

Gusset forming mode |

Vacuum mold forming |

Facial tissue machine: An Introduction

The facial tissue machine is a type of equipment that is used to manufacture and package facial tissues. It is an indispensable tool in modern-day life, and it has greatly contributed to making our lives easier and more comfortable. Below are some of the key things you need to know concerning facial tissue machines.

A facial tissue machine comprises several parts that work together to produce facial tissues. The basic components of the machine include a parent roll stand, embossing unit, perforation unit, cutting unit, and packing unit. The machine uses high-quality paper in the production of facial tissues, and the paper is usually fed into the machine using a parent roll stand. Once the paper is fed into the machine, it undergoes some vital processes such as embossing, perforation, cutting, and packaging to produce the final product. The machine is designed to produce a variety of facial tissues with different sizes, textures, and colors, depending on the specifications of the manufacturer.

There are diverse types of facial tissue machines that can be used to produce facial tissues. The choice of the machine that one will use depends on various factors such as the intended application, cost, and production capacity. Some of the common types of facial tissue machines include the single and double-handed inter fold machine, mini facial machine, pocket tissue machine, and boxed facial tissue machine. For industrial use, the high-speed facial tissue machines produce a large amount of facial tissues within a short period. The choice of the machine also determines the quality of the final product.

The facial tissue machine is commonly used in households and commercial establishments such as restaurants, hotels, and hospitals. The tissues produced by these machines are widely used to clean the face, nose, and hands. They are also used as a substitute for napkins. In addition, facial tissues are essential in the health sector since they are used to wipe away nasal secretions and mucus. In the hotel industry, facial tissues are essential in providing exceptional customer service and comfort.

In conclusion, the facial tissue machine is an indispensable machine that has transformed our lives by providing accessible, affordable, and reliable facial tissues. They are easily available, and they come in diverse sizes and colors that suit different preferences. The machine has made it possible for us to have clean faces, noses, and hands, no matter where we are.

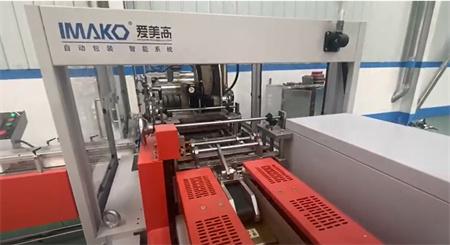

★TP-B30T automatic tissue bundle packing machine is suitable for auto bundle packing single soft pack facial tissue.

Equipped with bag opening detection protection function, air source management function, fault alarm display function, servo overload protection function.

Double column packaging, specification conversion, One click for size changing. It has the advantage of easy operation, high efficiency.

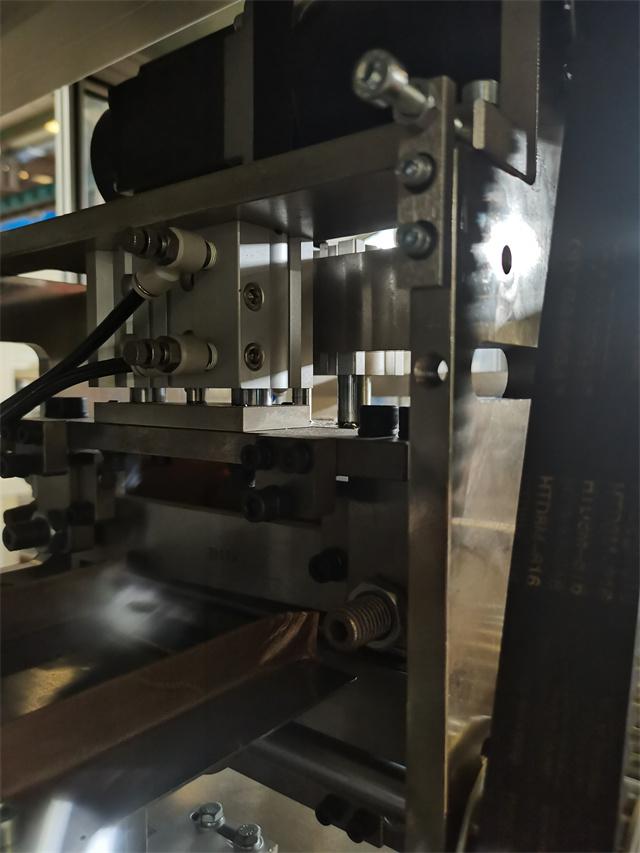

★ Adopts servos control for tissue arrangement, counting, stacking, tissue fill to bag, bag catching, bag conveying, bag opening and seal parts, This machine is easy to operation and ...

pIntroduction:/p Toilet tissue making machines are crucial in the production of toilet rolls that are widely used in homes, offices, and public facilities. These machines are designed t...

Finished Product ★Maximum stable packing speed of roll paper with core: 200 rolls/min ★Maximum stable packing speed of coreless roll paper: 150 rolls/min ★Can realize length ch...

TF-1500-2050 main parameter configuration Scope of application tissue paper,V Fold napkins, non-woven fabric Separator Servo drive Jumbo roll wid...

The Facial Tissue Making Machine exceeded our expectations in terms of efficiency and reliability.Nora 2024-06-06

The durability of this machine is impressive, it has been running smoothly without any major issues.Ava 2024-06-06

This machine has significantly increased our production output while maintaining consistent quality.Mila 2024-06-06

We appreciate the user-friendly interface and ease of operation of the Facial Tissue Making Machine.Addison 2024-06-06

we've been able to meet the growing demand for facial tissue products without any hassle.Hunter 2024-06-06