![]() Price: Negotiable

Price: Negotiable

![]() Model Number: TP-B30RE

Model Number: TP-B30RE

![]() Power: 25KW

Power: 25KW

![]() Application: Single Packed/Unpack Core/Coreless Roll Paper

Application: Single Packed/Unpack Core/Coreless Roll Paper

![]() Weight: 3400KG

Weight: 3400KG

![]() Output: 22 Pack/Min

Output: 22 Pack/Min

![]() Packaging dimension: Length (L): 300-690 Width (W): 160-440 Height (H): 80-280 mm

Packaging dimension: Length (L): 300-690 Width (W): 160-440 Height (H): 80-280 mm

![]() Place of Origin: CHINA.

Place of Origin: CHINA.

![]() Brand Name: IMAKO

Brand Name: IMAKO

![]() Certification: CE, ISO

Certification: CE, ISO

![]() Minimum Order Quantity: 1 SET

Minimum Order Quantity: 1 SET

![]() Trading Method: FOB/CIF/EXW Xiamen Port

Trading Method: FOB/CIF/EXW Xiamen Port

![]() Delivery Time: 90 Days

Delivery Time: 90 Days

![]() Packaging logistics: In wooded cases with fumigation finish or wrapped with plastic film.

Packaging logistics: In wooded cases with fumigation finish or wrapped with plastic film.

|

TP-B30RE main parameter configuration |

|

|

Specification\Model\ ltem |

TP-B30REV、TP-B30REM |

|

Scope of Application |

Core、coreless roll paper |

|

Feeding type |

ASF auto double lanes feeding system |

|

Design speed |

22 packs/min |

|

Stable speed |

20packs/min(relate to product size) |

|

Gusset type |

Vacuum forming mould |

|

Cut off modo |

lnsert & cut |

|

Bag storage structure |

Dual bag racks |

|

Bag storage qty |

600 bags |

|

Bag material |

PE film |

|

Compressed air(MAP) |

Pressure O.6MPA Flow 30l/min |

|

Power supply |

380V/50HZ |

|

Total motor power(KW) |

19 |

|

Machine weight (KG) |

3400 |

|

Bag type |

premade bag |

|

Servo control shaft nos |

10 |

|

Electrical control system |

VEICHI,MITSUBISHI |

|

Temp.system |

YUDILAN |

|

Pneumatic system |

SMC.AlRTAC |

|

Optional device |

lnk code printer.thermos transfer printer

|

Toilet paper is an essential item in our daily lives, and it's hard to imagine a world without it. Have you ever wondered how toilet paper is made and where it comes from? Well, in this article, we're going to explore the fascinating world of toilet paper machines and how they have transformed the manufacturing process of this everyday product.

The first toilet paper machine was invented in 1880 by the two brothers, Clarence and E. Irvin Scott. Before the invention of the toilet paper machine, toilet paper was made by hand, which was a time-consuming and expensive process. The Scott brothers' invention revolutionized the toilet paper industry by making it possible to produce large quantities of toilet paper more efficiently and at a lower cost.

A toilet paper machine is a complex piece of machinery that involves several processes to transform pulp into the final product. First, raw materials such as wood chips or recycled paper are dissolved in water to create a pulp. Then, the pulp is washed, refined, and bleached to create a clean, white pulp. Next, the pulp is fed into the paper machine, where it goes through several rollers, drying cylinders, and other equipment to create a continuous sheet of paper. Finally, the paper is cut into the desired size and packaged for distribution.

Over the years, toilet paper machines have undergone several advancements to improve their efficiency and productivity. One of the major developments has been the move towards automation, which has reduced the need for human labor and increased the speed of production. Another advancement has been the implementation of computer-controlled systems that monitor the entire production process and make adjustments to ensure consistent quality. These advancements have helped manufacturers to produce toilet paper more efficiently and at a lower cost while ensuring a consistent, high-quality product.

In conclusion, toilet paper machines have played a significant role in revolutionizing the toilet paper industry. From the invention of the first machine in the 1880s to the advancements of modern-day machines, these machines have transformed the way toilet paper is produced and made it accessible to everyone. Today, we take toilet paper for granted, but it's important to acknowledge the innovations that have made this everyday product a reality.

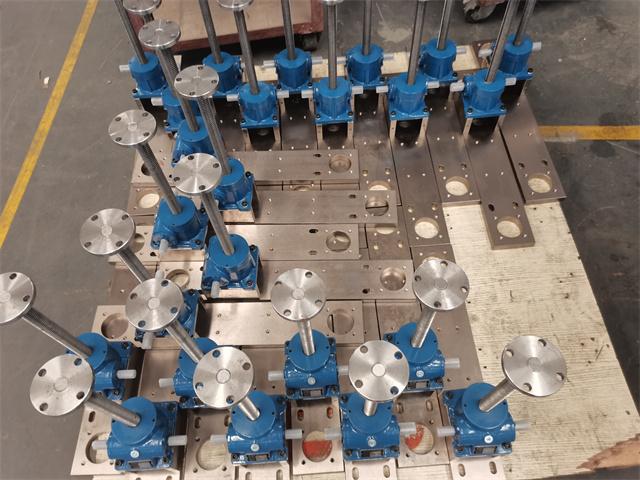

TP-B30RE series automatic roll paper bundle packing machine is suitable for automatic bundle packing single packed/unpack core/coreless roll paper.

Toilet paper is an essential item in our daily lives, and it's hard to imagine a world without it. Have you ever wondered how toilet paper is made and where it comes from? Well, in this...

Small scale tissue paper making machines are a great investment for those who want to start their own small business. These machines are affordable, easy to use and maintain, and can pr...

Main performance and structure features 1. Double transducer control, easy maintained, decreasing abrasion with long life. 2. human-machine operation, convenient and quick parame...

★This machine adopts PLC and 16 shafts servo movement controller for controlling unit, realize servo controlling for product conveying, flatting, counting, bag catch, bag open, tissue ...

We've seen a noticeable improvement in our packaging efficiency since implementingNathan 2024-06-05

The durability of this toilet roll pakaging machine ensures long-term performance, delivering consistent results day after day.Harper 2024-06-05

this Toilet Paper Rolls Packing Machine has streamlined our packaging process, saving us time and resourcesCamila 2024-06-05

our staff quickly learned to operate this toilet paper packing machine without extensive training.lisa 2024-06-05

design allows us to maximize space in our facility, optimizing our workflow.Hazel 2024-06-05