![]() Price: Negotiable

Price: Negotiable

![]() Model Number: TP-R220

Model Number: TP-R220

![]() Power: 15.2KW,380V/60Hz

Power: 15.2KW,380V/60Hz

![]() Application: Single core and coreless toilet paper rolls

Application: Single core and coreless toilet paper rolls

![]() Weight: 1800KG

Weight: 1800KG

![]() Output: 200 Packs/Min

Output: 200 Packs/Min

![]() Packaging dimension: Length (L): 80-220 Diameter(D) 80-130 mm

Packaging dimension: Length (L): 80-220 Diameter(D) 80-130 mm

![]() Place of Origin: CHINA.

Place of Origin: CHINA.

![]() Brand Name: IMAKO

Brand Name: IMAKO

![]() Certification: CE, ISO

Certification: CE, ISO

![]() Minimum Order Quantity: 1 SET

Minimum Order Quantity: 1 SET

![]() Trading Method: FOB/CIF/EXW Xiamen Port

Trading Method: FOB/CIF/EXW Xiamen Port

![]() Delivery Time: 90 Days

Delivery Time: 90 Days

![]() Packaging logistics: In wooded cases with fumigation finish or wrapped with plastic film.

Packaging logistics: In wooded cases with fumigation finish or wrapped with plastic film.

2. human-machine operation, convenient and quick parameter setting.

3. Self diagnosis failure function, clear failure display.

4. High sensitivity optical electric color mark tracking AND digital input cut position which makes the sealing and cutting more accurate.8. All the controls are achieved by software, convenient for function adjusting and upgrading.

|

TP-R220 main parameter configuration |

||

|

Design packing speed |

220packs/min |

|

|

Stable packing speed |

≤200 pack/min |

relate to product size |

|

Maximum flm width(mm) |

430 |

|

|

Cutter configuration |

Double cutters |

|

|

Film install structure |

Air shaft |

|

|

Machine weight(KG) |

1800 |

|

|

Machine noise(db) |

≤78dB |

|

|

Percentage of pass |

≥97% |

|

|

Efficiency |

≥85% |

|

|

Power supply |

380V/60Hz |

|

|

Packaging film material |

BOPP、Spp |

|

|

Film thickness |

0.018-0.03 |

|

Manufacturing toilet paper is a booming business around the world. The toilet paper manufacturing machine has become an essential tool in this process. This machine produces high-quality toilet paper in various sizes and textures, making it a popular choice for commercial and residential use. In this article, we will explore the various features and benefits of the toilet paper manufacturing machine.

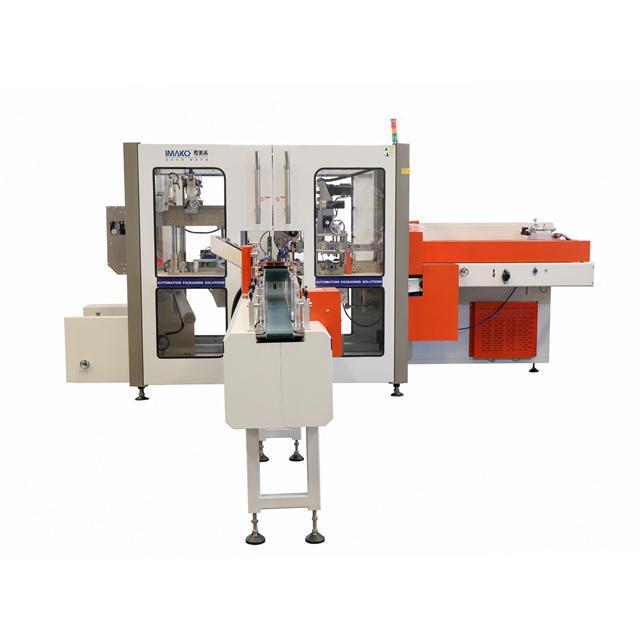

Suitable for packing roll paper, such as roll tissue, code applying paper and cash register paper etc.

|

Max. Work Speed: |

200Pack/min |

|

Total Power: |

12KW |

|

Pack Range(mm): |

Length (L): 80-220 Diameter (D): 80-130 |

The toilet paper manufacturing machine is designed for high-speed and efficient production. It can produce large quantities of toilet paper rolls in a relatively short amount of time, making it a highly profitable investment for any business. This machine is specially designed to handle large volumes of paper without causing any damage to the final product. With its advanced technology, the toilet paper manufacturing machine can produce high-quality toilet paper rolls, meeting the demands of customers worldwide.

The toilet paper manufacturing machine is designed to meet the unique needs of different customers. It comes with customizable settings that allow users to adjust the roll size, texture, and other specifications according to their requirements. This flexibility enables businesses to cater to a wide range of customers, thus increasing their profits. Moreover, the machine's modular design allows for easy maintenance and upgrades, ensuring that it remains in top-notch condition for years to come.

The toilet paper manufacturing machine is environment-friendly as it uses recycled paper as raw material. This not only reduces waste but also conserves energy, making it a sustainable option for businesses. Additionally, the machine's advanced technology reduces energy consumption, further reducing its carbon footprint. With increasing global concerns about the environment, using such machines helps businesses make a positive impact on the planet.

In conclusion, the toilet paper manufacturing machine is a vital tool for any business that wants to produce high-quality toilet paper efficiently, sustainably, and profitably. With its advanced technology, customizable settings, and environmentally-friendly operations, it is no surprise that the demand for this machine continues to grow worldwide.

General function

Link conveyor system, auto monitor in feed rolls flow, machine auto-stop for limited rolls, rolls auto arrange and feed function, auto stop for abnormal operation and no facial tissue condition, auto alarm and stop for no film, film cutting position electronic auto adjust function, auto-memory and keep parameters function, main machine jog and separated action function, side-sealing part separated action function, whole machine linkage and emergency stop function, whole machine cycle stop and auto display defaults function.

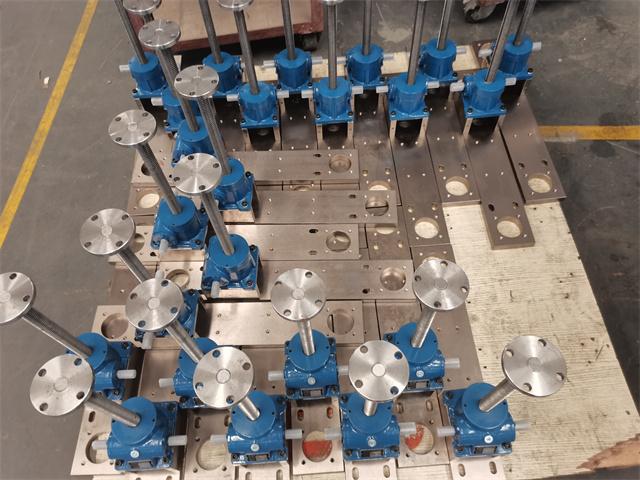

Main performance and structure features 1. Double transducer control, easy maintained, decreasing abrasion with long life. 2. human-machine operation, convenient and quick parame...

★This machine adopts PLC and 16 shafts servo movement controller for controlling unit, realize servo controlling for product conveying, flatting, counting, bag catch, bag open, tissue ...

Toilet paper is an essential item in our daily lives, and it's hard to imagine a world without it. Have you ever wondered how toilet paper is made and where it comes from? Well, in this...

When it comes to toilet paper production, the fully automatic toilet paper making machine is a game changer. This advanced technology makes it possible for companies to produce high-qua...

our staff quickly learned to operate this toilet paper packing machine without extensive training.lisa 2024-06-05

The durability of this toilet roll pakaging machine ensures long-term performance, delivering consistent results day after day.Harper 2024-06-05

design allows us to maximize space in our facility, optimizing our workflow.Hazel 2024-06-05

We've seen a noticeable improvement in our packaging efficiency since implementingNathan 2024-06-05

this Toilet Paper Rolls Packing Machine has streamlined our packaging process, saving us time and resourcesCamila 2024-06-05